Vacuum forming machine(51)

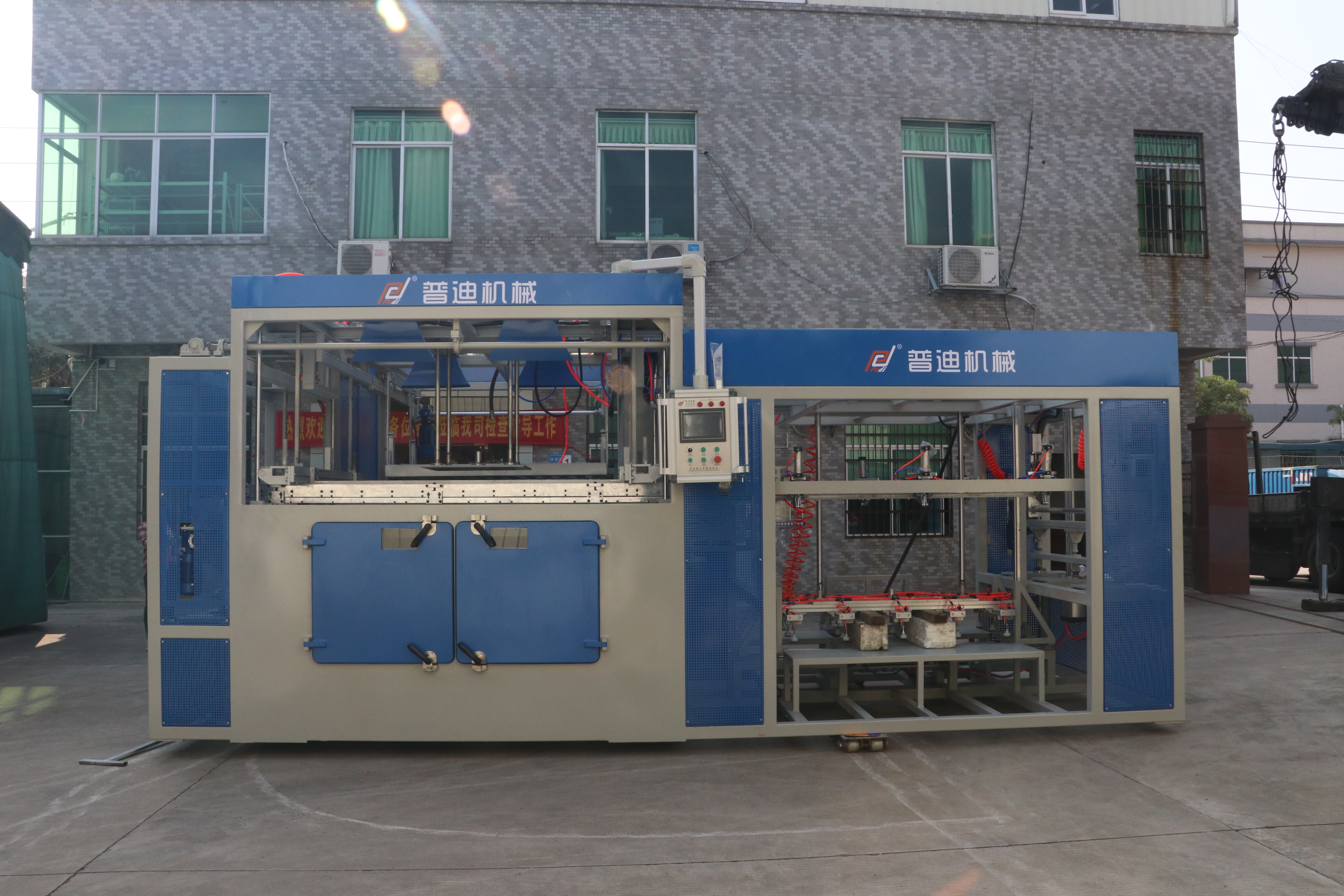

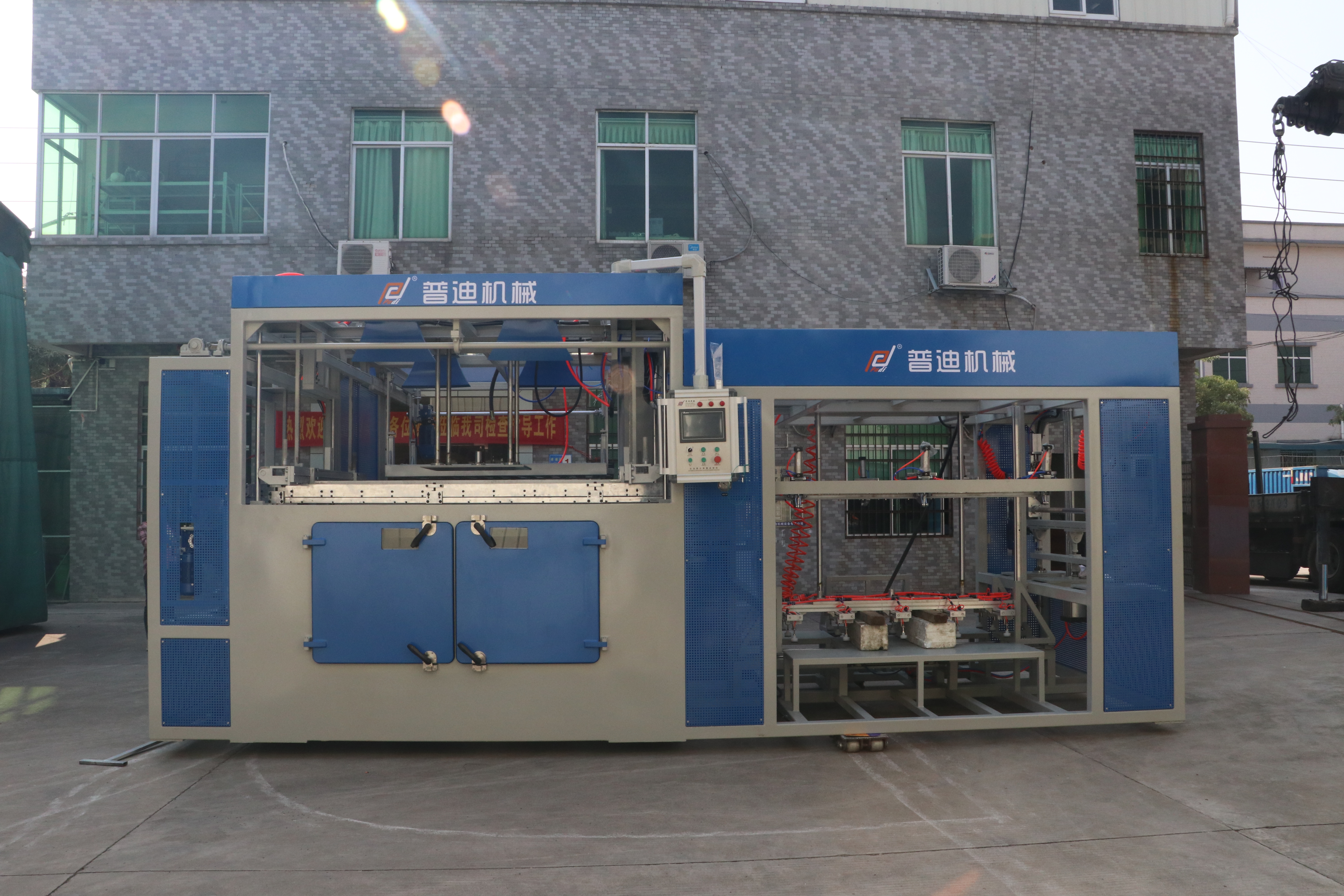

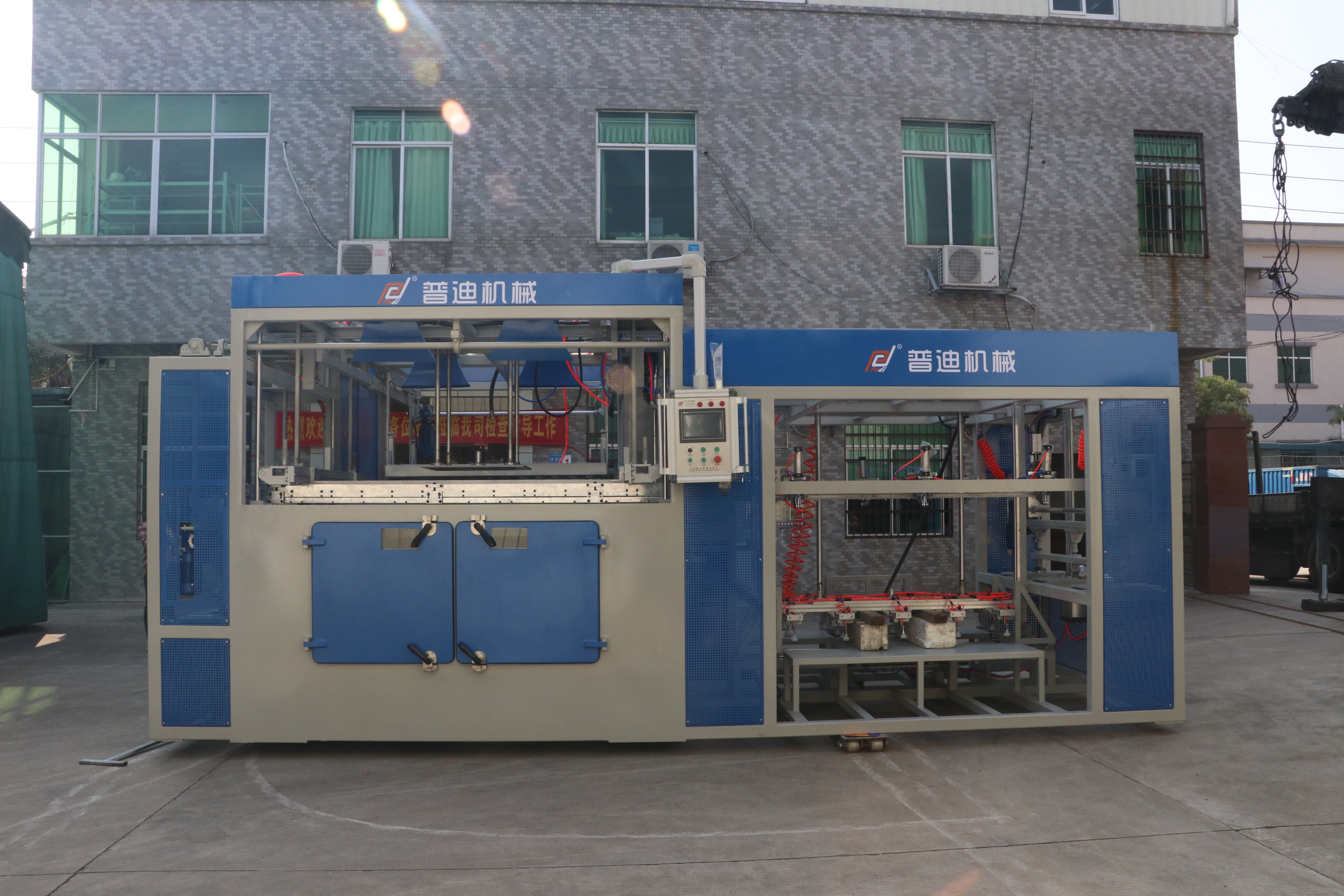

twin-sheet forming

The twin-sheet forming is equipped with an advanced heating and cooling system that can heat and cool the material quickly and evenly, minimizing production cycles and enhancing efficiency. The motor is very strong but it’s also energy-saving, it will make function in necessary time to prevent waste. Each component is suitable for international standard, so it’s easy to maintain and install.

Door Panel Vacuum Forming Machin

The door panel vacuum forming machine has a high flexibility, you can easily operate the machine with simple instruction. It can not only support you with low input, but also bring a high output. It can easily control and trace the process, getting your production purpose, which both save the time to wait for the mould and to change mould, at the same time, it also improves the production efficiency. The biggest function is that it can accurately match with your specific production demands.

Double station vacuum forming

The double station vacuum forming machine can be used in small space, and it can fast work out of the limit of vacuum room. The screen will show the temperature, pressure, and location, so you can freely adjust it. It can keep the heating board in constant temperature to prevent danger. It is suitable for thermoforming of composite materials, carbon fiber, glass fiber, etc.

pressure forming machine

The pressure forming machine has low-temperature design, the products can fast demould from the mold without any stick, it can be easily operated. It is made of steel and with touch screen, very easy to clean and maintain. There are anti-pressure accidental safety device, so you do not worry about the working and human safety. The appearance looks like advanced, if your customers see the machine, they will all praise and surprise for it.

Peripheral equipment(4)

Vacuum Blister Mold

The vacuum blister mold is durable and long-lasting, the time to manufacture is short, so you can receive it as quick as possible, but if the mould you showed us is too complicated, it may need to spend more time on making. The molds have lower tooling costs than traditional molding methods, making them cost-effective for small to medium production runs. Besides, it can make the products produced with a smooth and uniform surface finish, reducing the need for additional finishing processes.

cutting machine

The cutting machine has stable pressure, so it can cut materials with high precision, ensuring accurate cuts and reducing material waste, which makes it stand for many years. It can also cut materials at a much faster rate than traditional cutting methods, increasing productivity and reducing lead times. Whatever the material is, it can cut a wide range of materials, including metals, plastics, and fabrics, making them suitable for a variety of applications.

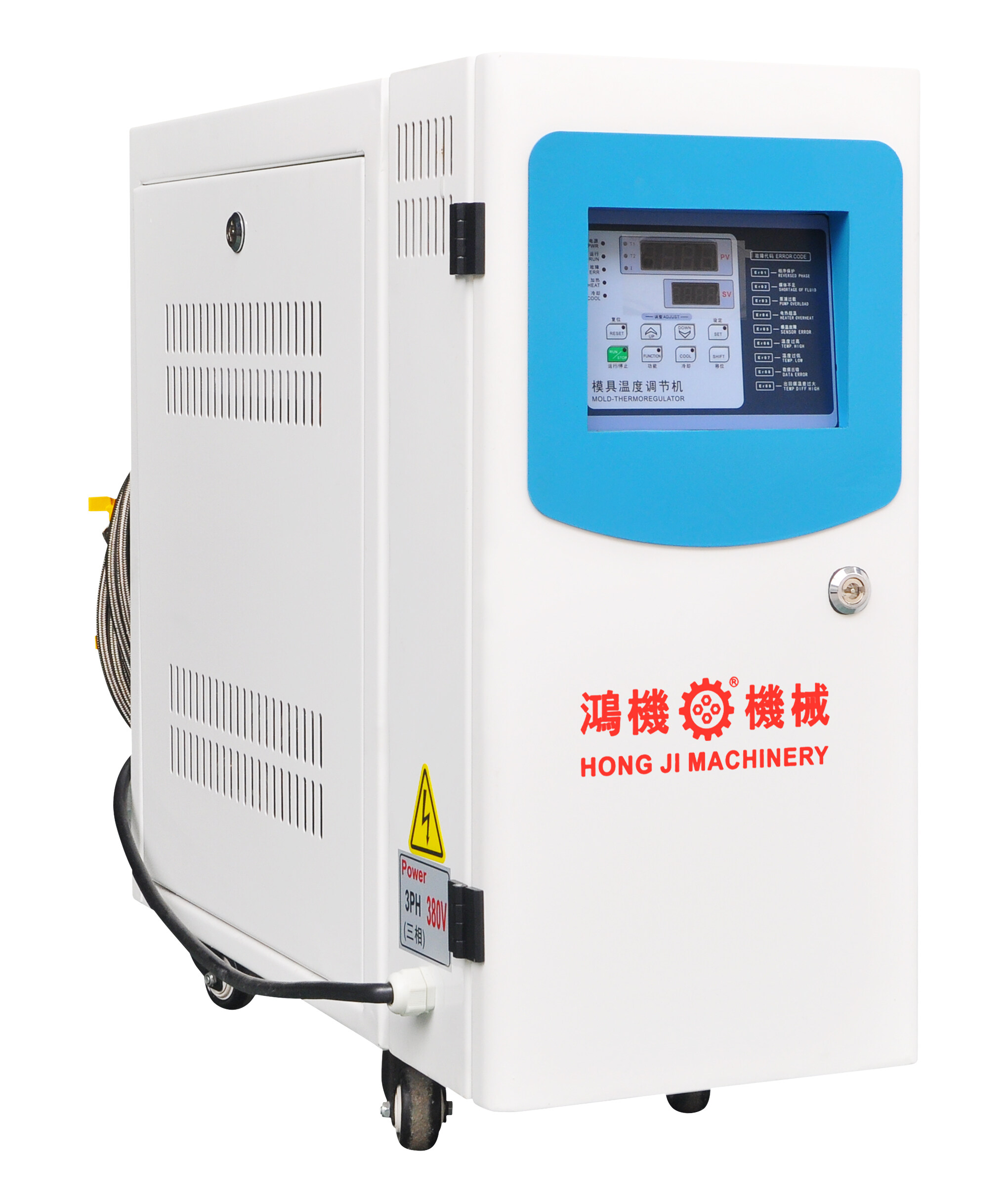

Mold temperature machine

The mold temperature machine shows real temperature with easy operation. It has multiple temperature zones, allowing you to control the temperature of different parts of the mold independently, ensuring optimal temperature distribution and reducing the risk of defects. The design of the electric control box isolated from the fuselage is to prolong the life of the electric appliance. The most important is the safety, it has 10+ safety protection functions, and automatically make power off.

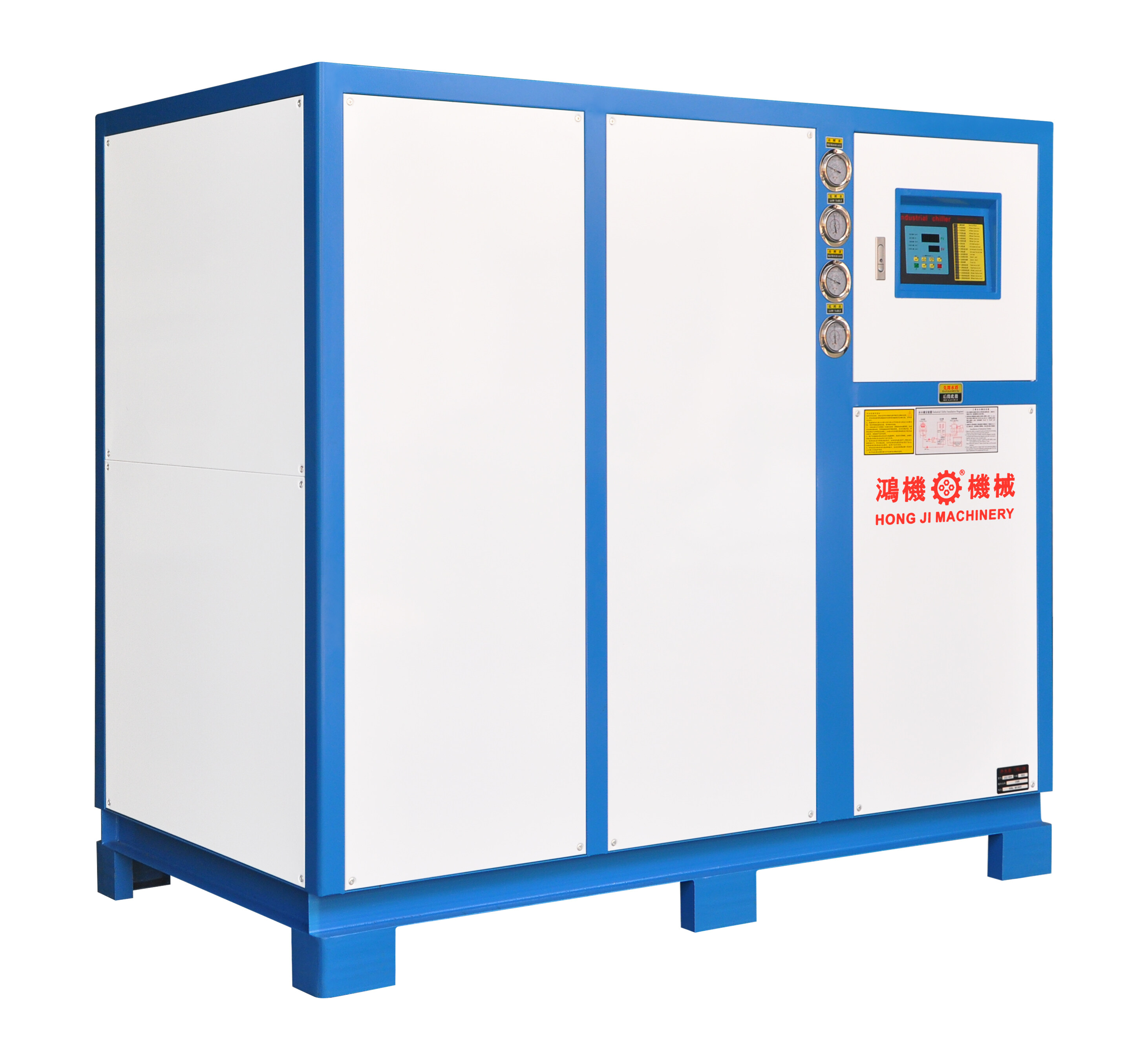

chiller

The chiller can be automatically controlled with multiple protection, it’s easy to use and maintain, which is also convenient to repair. It has the touch screen controller to set up your parameters, and it can monitor itself with automatic open and stop, which can be showed with dynamic status. If you worry about that it will makes large energy, you are wrong, it can save energy with the green purpose to protect environment.