Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

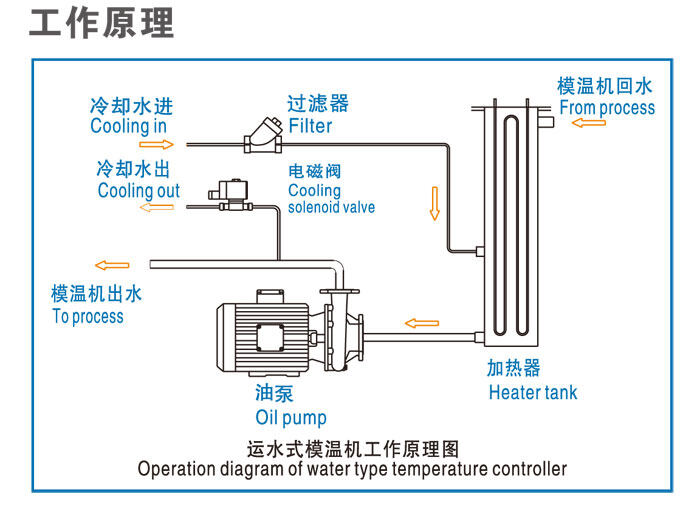

The mold temperature machine shows real temperature with easy operation. It has multiple temperature zones, allowing you to control the temperature of different parts of the mold independently, ensuring optimal temperature distribution and reducing the risk of defects. The design of the electric control box isolated from the fuselage is to prolong the life of the electric appliance. The most important is the safety, it has 10+ safety protection functions, and automatically make power off.

Accurate:

The machine is built with a robust construction, using high-quality materials that can withstand the high temperatures and pressures of the injection molding process, ensuring accurate temperature control over time. And it is equipped with automated controls that can monitor and adjust the temperature of the mold, ensuring consistent product quality and reducing operator error. The machine boasts of user-friendly controls that facilitate effortless operation and adjustment, empowering manufacturers to fine-tune temperature settings to suit diverse materials and products.

Secure:

The machine is equipped with safety interlocks that prevent the machine from operating if the doors or covers are open, ensuring that operators cannot access the mold while it is in operation. The overheating protection can automatically shut down the machine if the temperature exceeds a certain limit, preventing damage to the mold and the machine. It’s designed and manufactured in compliance with safety standards and regulations, ensuring that it meets the highest safety standards. Besides, it has emergency stop buttons that can immediately stop the machine in case of an emergency, preventing you from accidents and injuries.

Improve the Molding Efficiency:

Before molding, the mold temperature is automatically controlled to quickly reach the required temperature and maintain a constant temperature, reducing the required time for mold preheating. It can be operated continuously without worrying about the mold temperature being too high, and meeting the problem that it is suddenly stopped on the way does not need to wait for the temperature to rise due to the drop of the mold temperature, so the production efficiency can be improved and the production progress can be accelerated.

Product Parameter:

|

Item |

Unit |

JJS-05 |

JJS-10 |

JJST-10 |

JJST-20 |

|

Temp control range |

℃ |

Inlet water temperature+15℃-180℃ |

|||

|

Temp control accuracy |

℃ |

PID±0.5℃ |

|||

|

Power supply |

|

AC3&380V 50HZ 3P+E |

|||

|

Heat transferring medium |

|

water |

|||

|

Cooling method |

|

Direct(indirect)cooling |

|||

|

Heating capacity |

Kw |

6 |

9 |

9 |

12 |

|

Horsepower of pump |

Hp |

0.5 |

1 |

1 |

2 |

|

Working pressure oconsumption |

Kg/cm² |

1.8 |

1.5 |

1.7 |

2.0 |

|

Maximum power consumption |

KW |

7 |

10 |

10 |

14 |