Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

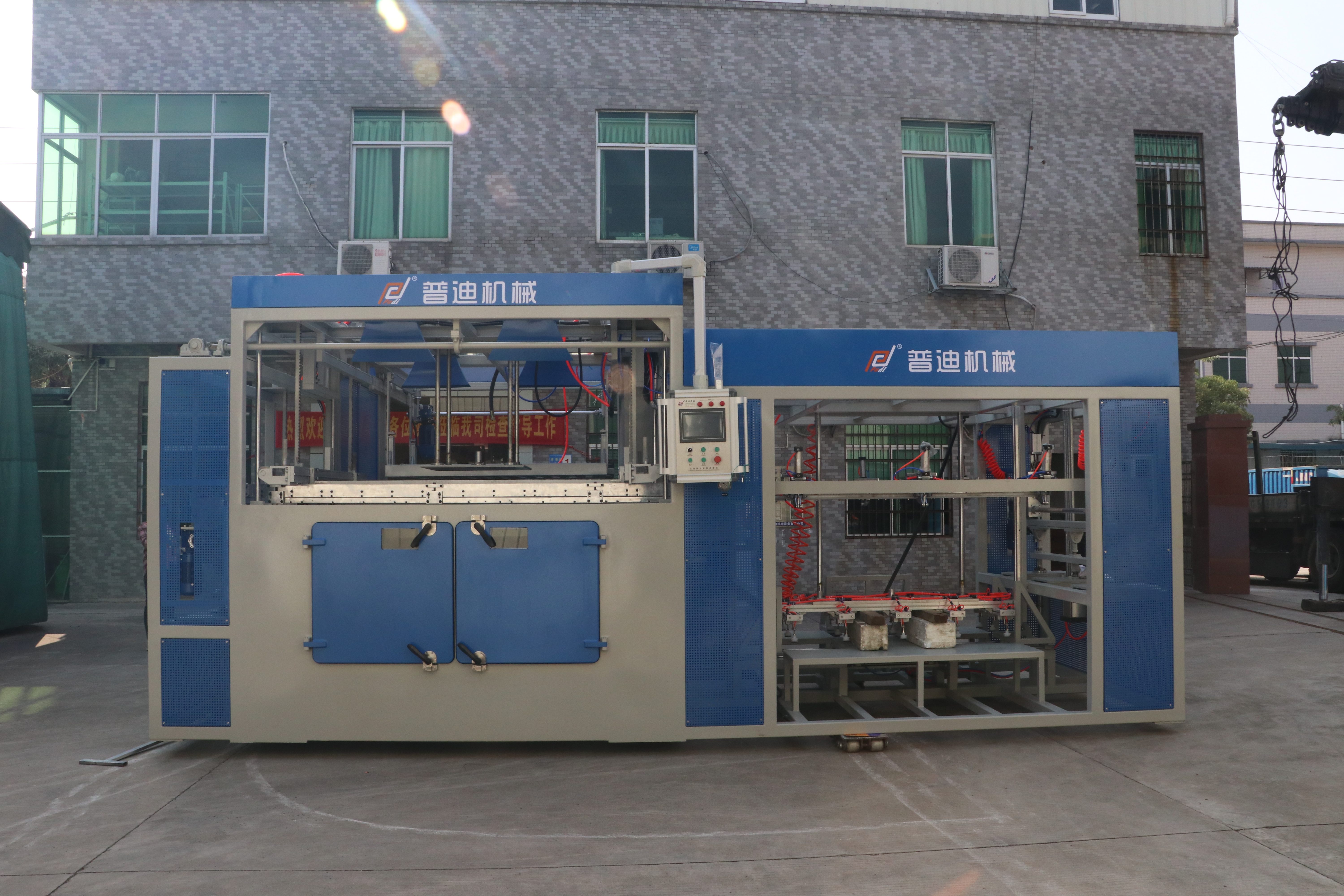

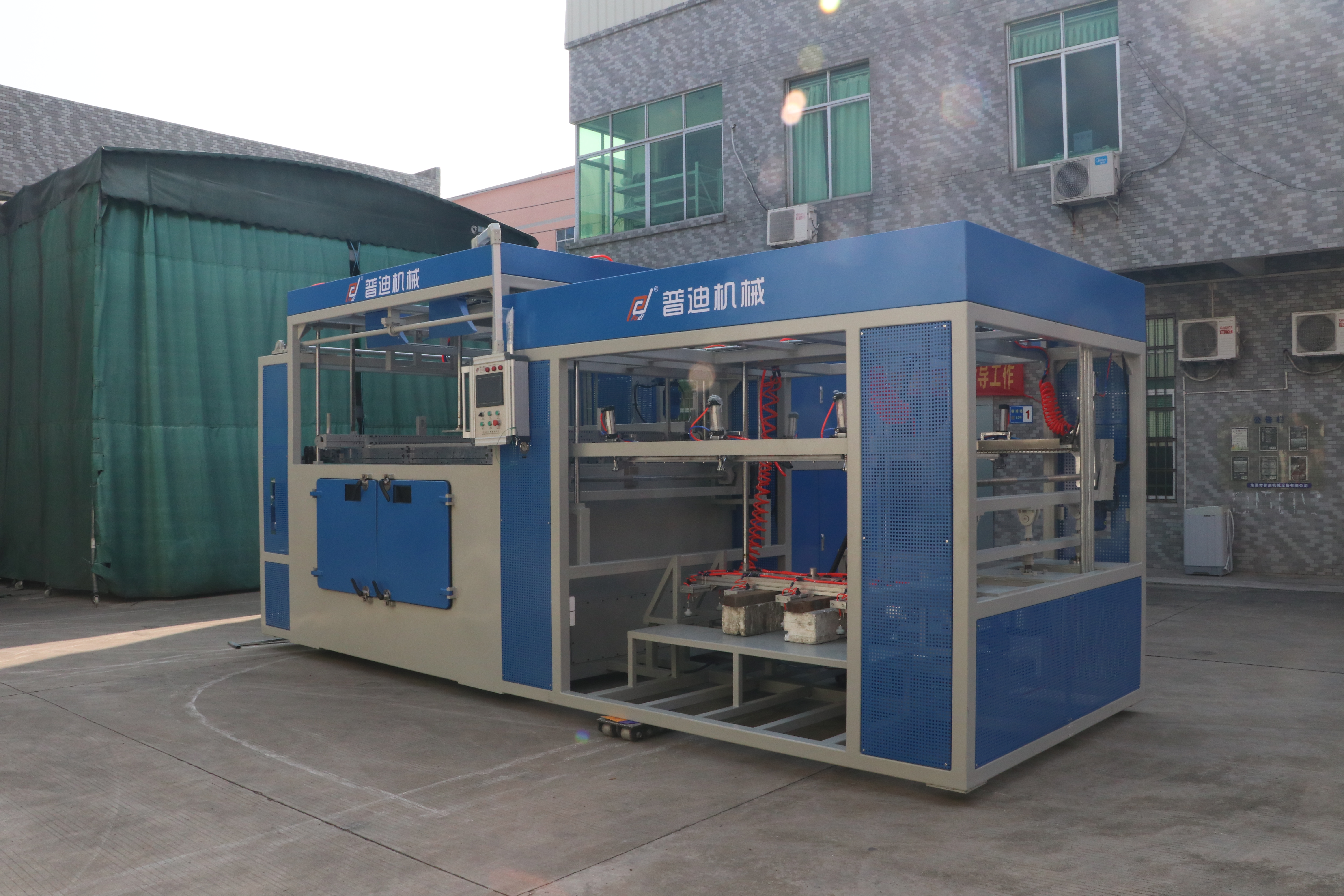

The pressure forming machine has low-temperature design, the products can fast demould from the mold without any stick, it can be easily operated. It is made of steel and with touch screen, very easy to clean and maintain. There are anti-pressure accidental safety device, so you do not worry about the working and human safety. The appearance looks like advanced, if your customers see the machine, they will all praise and surprise for it.

Easy to Maintain:

The machine is built with high-quality, durable components that require minimal maintenance and have a long lifespan, and has a simple design that makes it easy to access and maintain its components. It is designed with a modular construction that allows for easy replacement of parts and components, reducing downtime and maintenance costs.

Besides, the machine comes with a regular maintenance schedule that outlines the necessary maintenance tasks and intervals, making it easy for operators to keep the machine in good working condition.

Advanced Appearance:

The machine is designed with modern aesthetics that give it a sleek and sophisticated appearance, making it visually appealing and attractive to customers. The machine is built with high-quality materials, such as stainless steel and carbon steel, that give it a premium look and feel with multifunctional features. It is designed with attention to detail, such as smooth edges and clean lines, that give it a polished appearance and enhance its overall aesthetic.

Product Parameter:

|

Maximum Forming Area |

1600mm*1600mm |

|

Forming Thickness |

0.4-1.5mm |

|

Product Forming Height |

180mm |

|

Furnace Length |

1650mm |

|

Total Power of Electric Furnace |

102KW |

|

Vacuum Pump |

5.5KW (with vacuum storage tank) |

|

Pulling Servo |

4.5KW |

|

Total Power |

120KW (normal use power: 40-60KW) |

|

Vacuum |

200m³/h |

|

Work Efficiency |

15-30s/mode (this parameter determines the length of time according to different product thicknesses) |

|

Total Air Source (external configuration) |

0.6-0.8Mpa |

|

Power Supply |

380V/50HZ (4+1 cable 50 m²) |

|

Rails |

Steel Girder |

|

Zipper Chain |

KMC Double Row B Chain (made in Taiwan) |

|

Main Frame |

Channel steel, steel plate, angle iron and stainless steel are national standards |

|

Body Sheet Metal |

Baking Paint and Electroplating Treatment |

|

Total Equipment Weight (reference) |

6.5T |

|

Machine Size (footprint area) |

10000mm*3000mm*2800mm |

Application: