Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

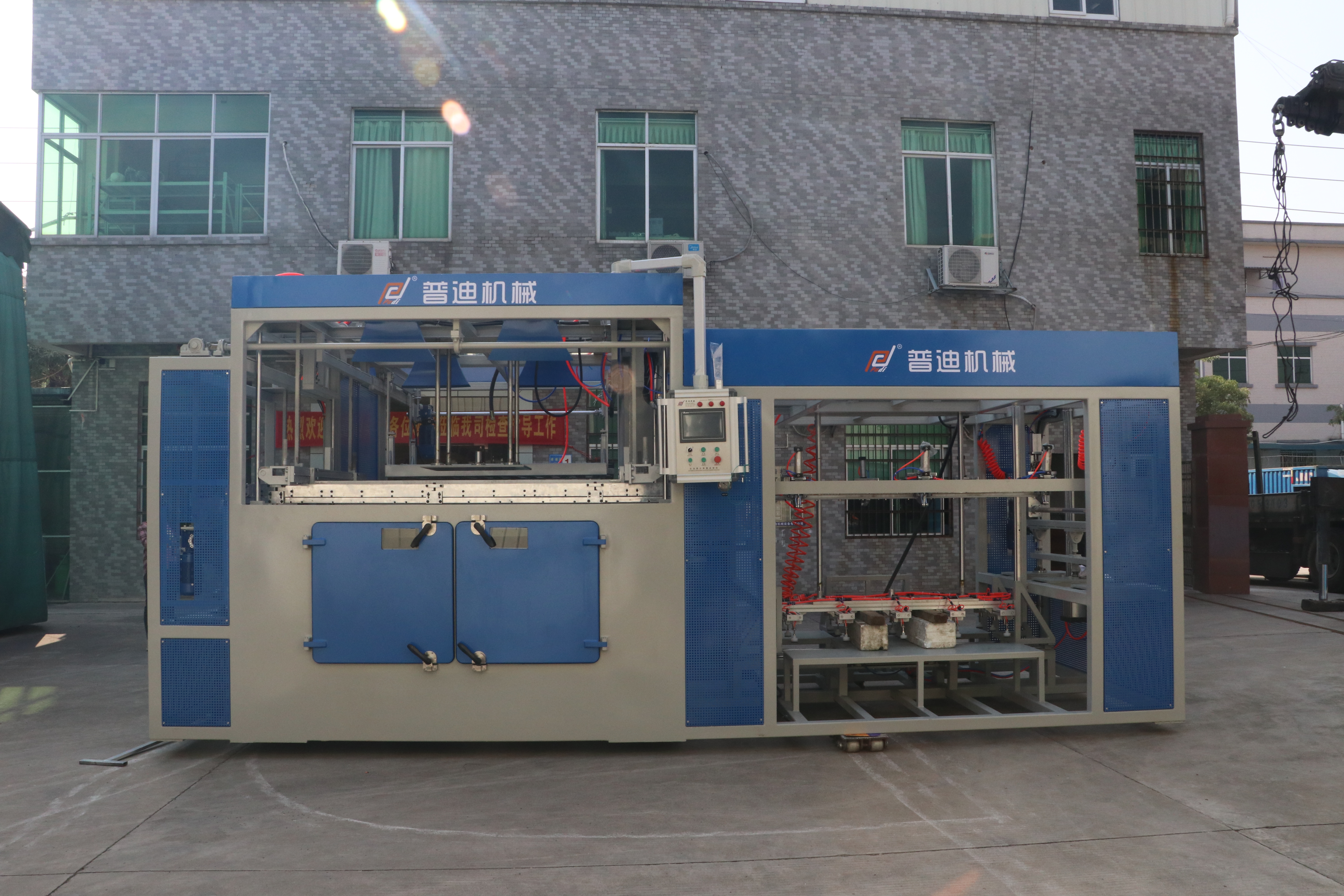

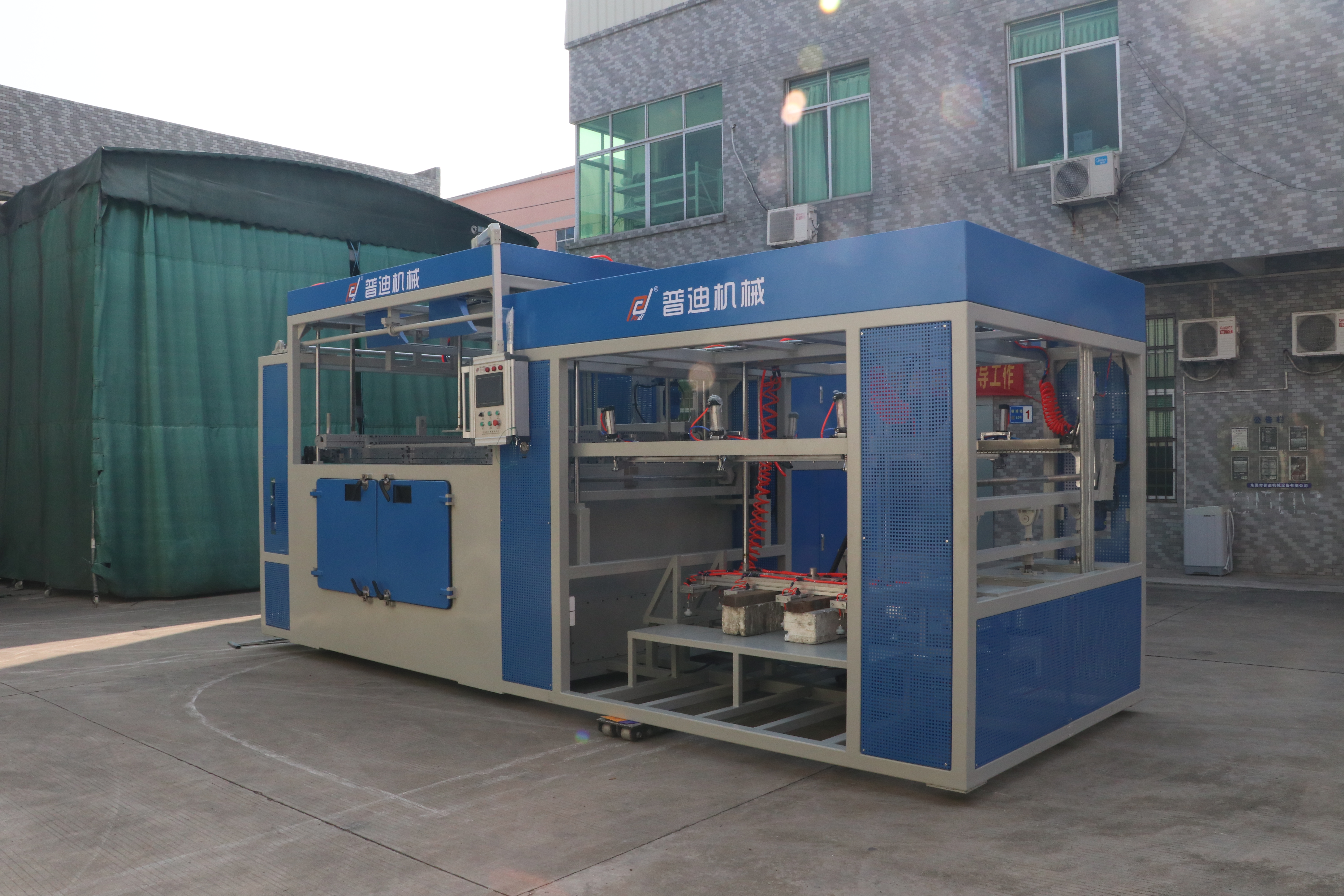

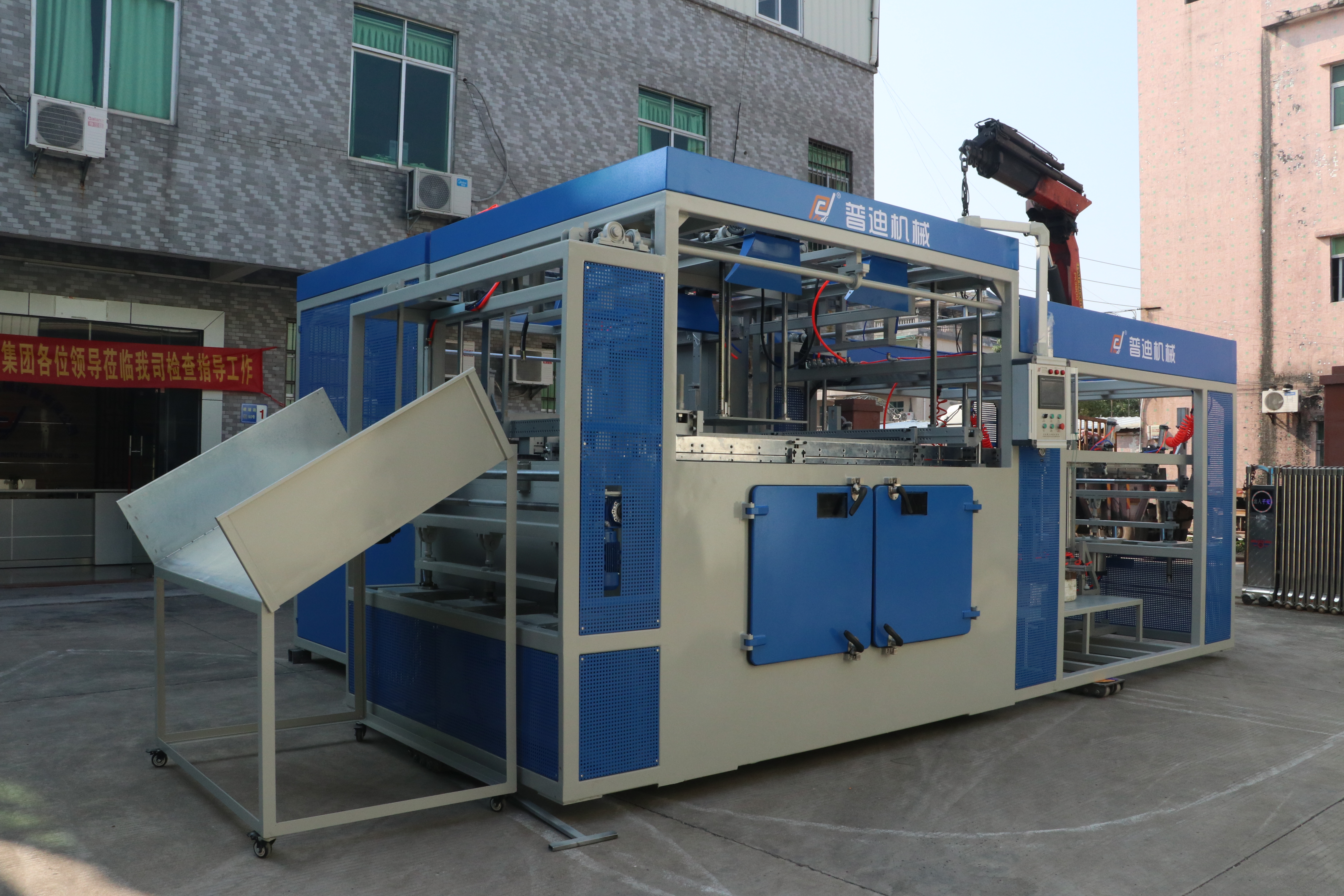

The door panel vacuum forming machine has a high flexibility, you can easily operate the machine with simple instruction. It can not only support you with low input, but also bring a high output. It can easily control and trace the process, getting your production purpose, which both save the time to wait for the mould and to change mould, at the same time, it also improves the production efficiency. The biggest function is that it can accurately match with your specific production demands.

Flexible:

The machine is easy to operate, with user-friendly controls and intuitive interfaces, making it accessible to operators with different levels of experience. It is customized, allowing manufacturers to add features and components that suit their specific forming needs, such as multiple heating zones and adjustable clamping systems.

Product Parameter:

|

Maximum Forming Area |

1600mm*1600mm |

|

Forming Thickness |

0.4-1.5mm |

|

Product Forming Height |

180mm |

|

Furnace Length |

1650mm |

|

Total Power of Electric Furnace |

102KW |

|

Vacuum Pump |

5.5KW (with vacuum storage tank) |

|

Pulling Servo |

4.5KW |

|

Total Power |

120KW (normal use power: 40-60KW) |

|

Vacuum |

200m³/h |

|

Work Efficiency |

15-30s/mode (this parameter determines the length of time according to different product thicknesses) |

|

Total Air Source (external configuration) |

0.6-0.8Mpa |

|

Power Supply |

380V/50HZ (4+1 cable 50 m²) |

|

Rails |

Steel Girder |

|

Zipper Chain |

KMC Double Row B Chain (made in Taiwan) |

|

Main Frame |

Channel steel, steel plate, angle iron and stainless steel are national standards |

|

Body Sheet Metal |

Baking Paint and Electroplating Treatment |

|

Total Equipment Weight (reference) |

6.5T |

|

Machine Size (footprint area) |

10000mm*3000mm*2800mm |

Why Choose Us?