Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

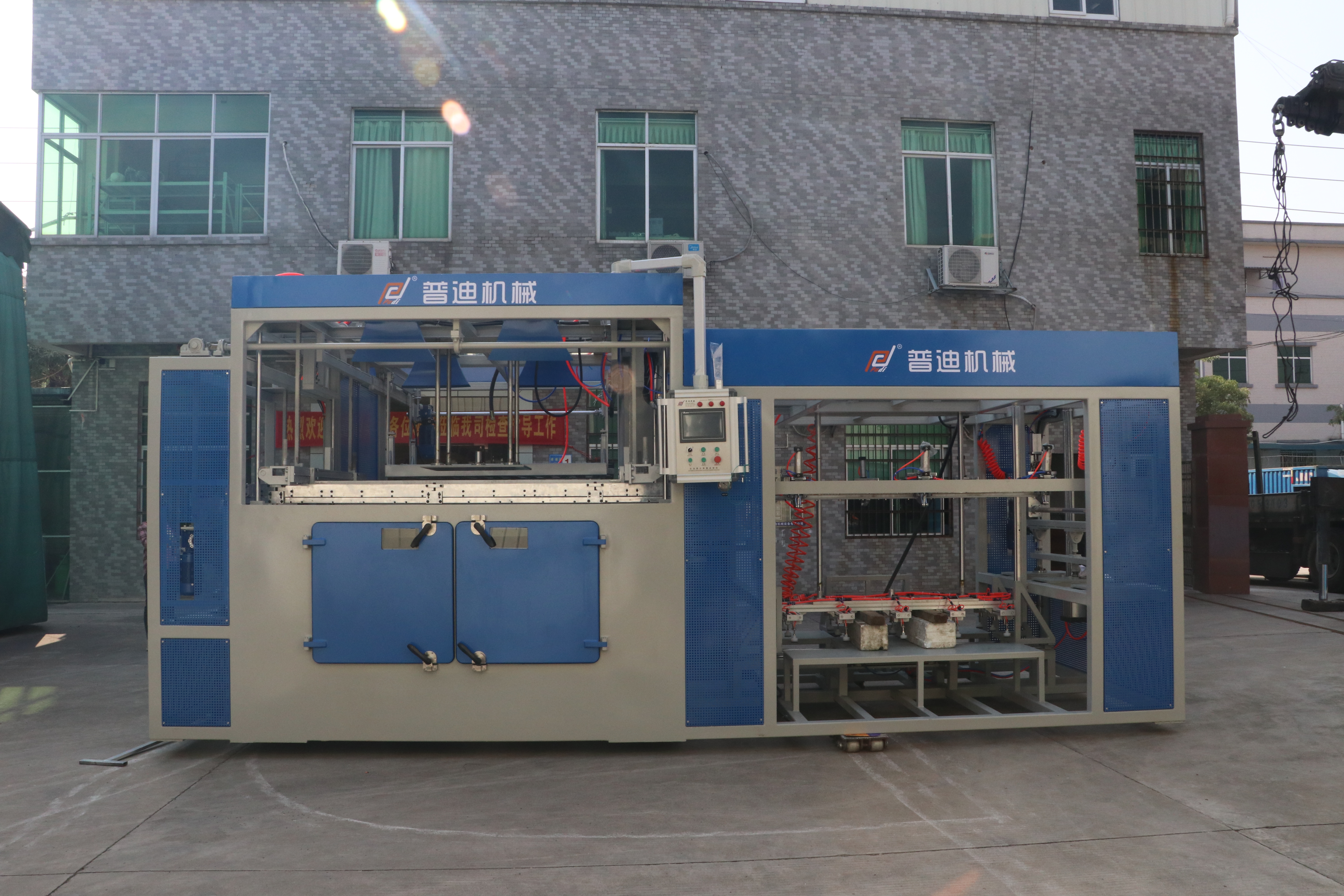

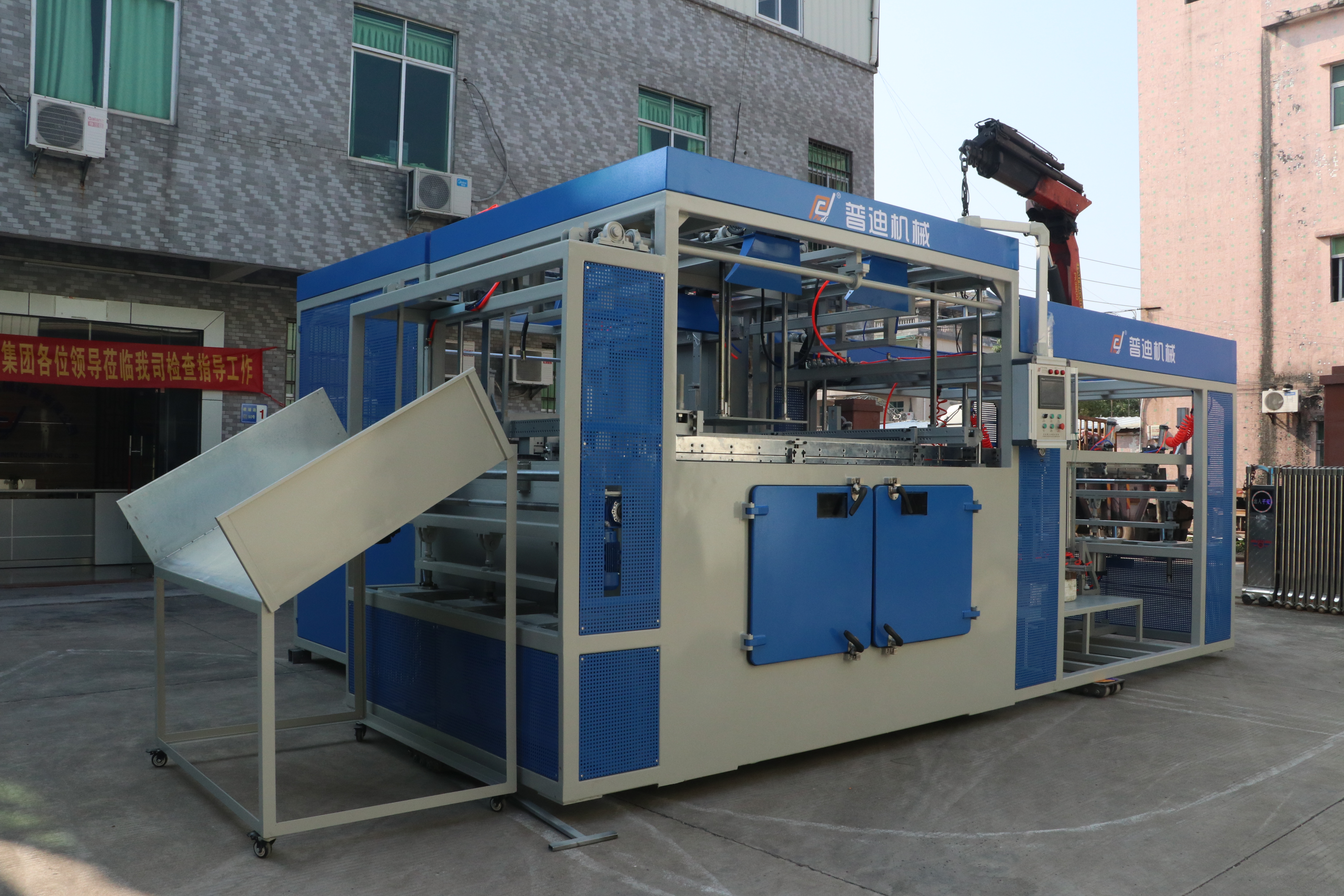

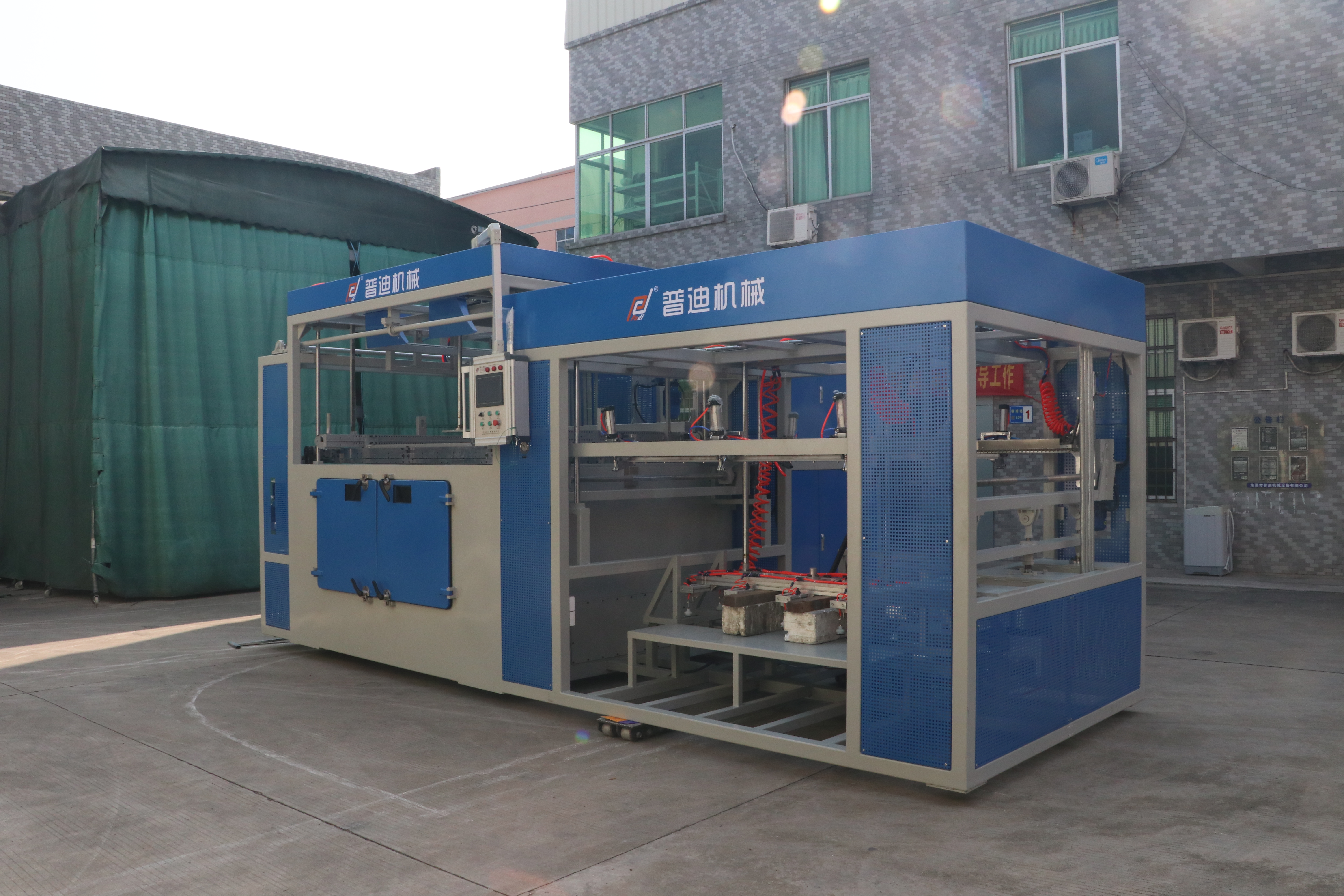

The high speed double plate forming machine has good sealing with high stability and strength, and it’s easy to install and maintain. The volume is small, and you can customize the volume for your wanted. The power for moulding is very strong, very suitable for different complicated products. The compact construction makes it accurately control the manufacture, thereby improve the production efficiency. The most important is that it can well prevent the oil temperature too high, the cooling system can make it well cool down.

Small Volume:

The machine is specially designed to be compact, which means that it takes up less space in the production facility. It can operate efficiently, which means that it can produce a high volume of products in a short amount of time, despite its small size. The machine boasts an automated material handling system that obviates the necessity for manual handling of raw materials, which reduces the need for additional space for material storage and handling.

Good Cooling System:

The machine is equipped with a double plate design that allows for the forming of two products simultaneously, which generates more heat during the forming process. A good cooling system is necessary to prevent overheating and ensure consistent product quality. Besides, the machine has the capacity to manufacture a substantial quantity of products within a brief duration, which generates more heat and requires a good cooling system to maintain optimal operating temperatures.

Product Parameter:

|

Maximum Forming Area |

1600mm*1600mm |

|

Forming Thickness |

0.4-1.5mm |

|

Product Forming Height |

180mm |

|

Furnace Length |

1650mm |

|

Total Power of Electric Furnace |

102KW |

|

Vacuum Pump |

5.5KW (with vacuum storage tank) |

|

Pulling Servo |

4.5KW |

|

Total Power |

120KW (normal use power: 40-60KW) |

|

Vacuum |

200m³/h |

|

Work Efficiency |

15-30s/mode (this parameter determines the length of time according to different product thicknesses) |

|

Total Air Source (external configuration) |

0.6-0.8Mpa |

|

Power Supply |

380V/50HZ (4+1 cable 50 m²) |

|

Rails |

Steel Girder |

|

Zipper Chain |

KMC Double Row B Chain (made in Taiwan) |

|

Main Frame |

Channel steel, steel plate, angle iron and stainless steel are national standards |

|

Body Sheet Metal |

Baking Paint and Electroplating Treatment |

|

Total Equipment Weight (reference) |

6.5T |

|

Machine Size (footprint area) |

10000mm*3000mm*2800mm |

Application: