Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

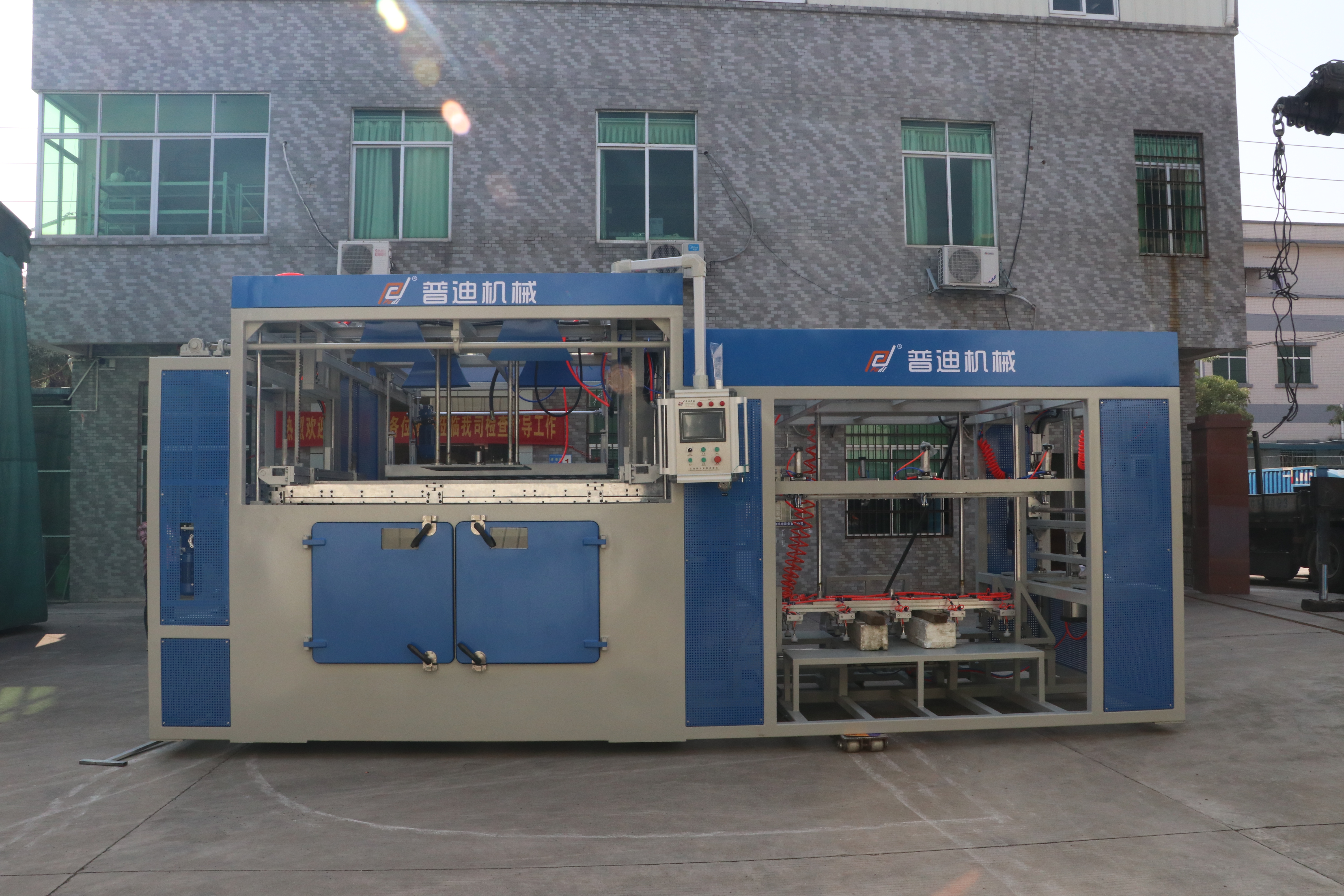

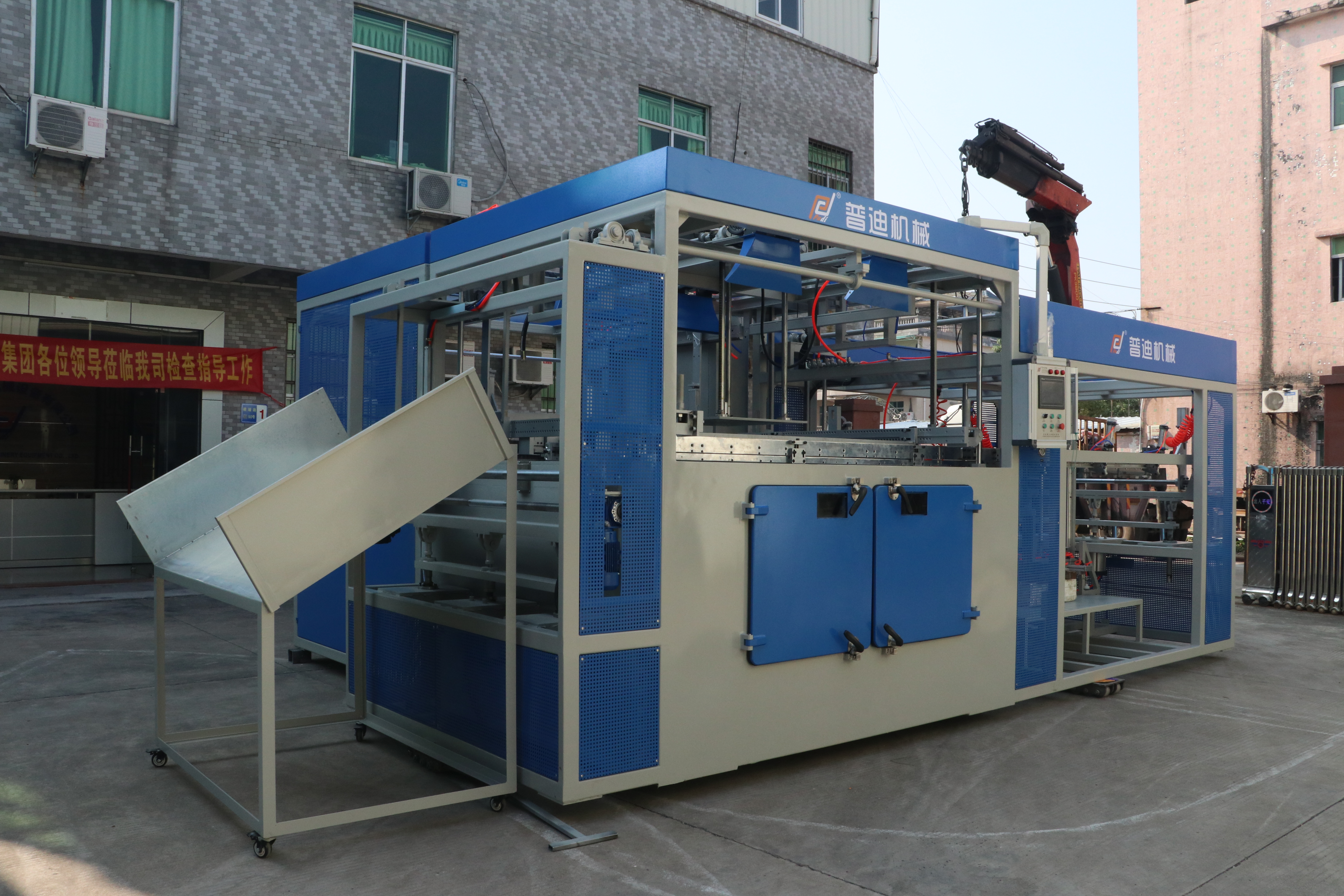

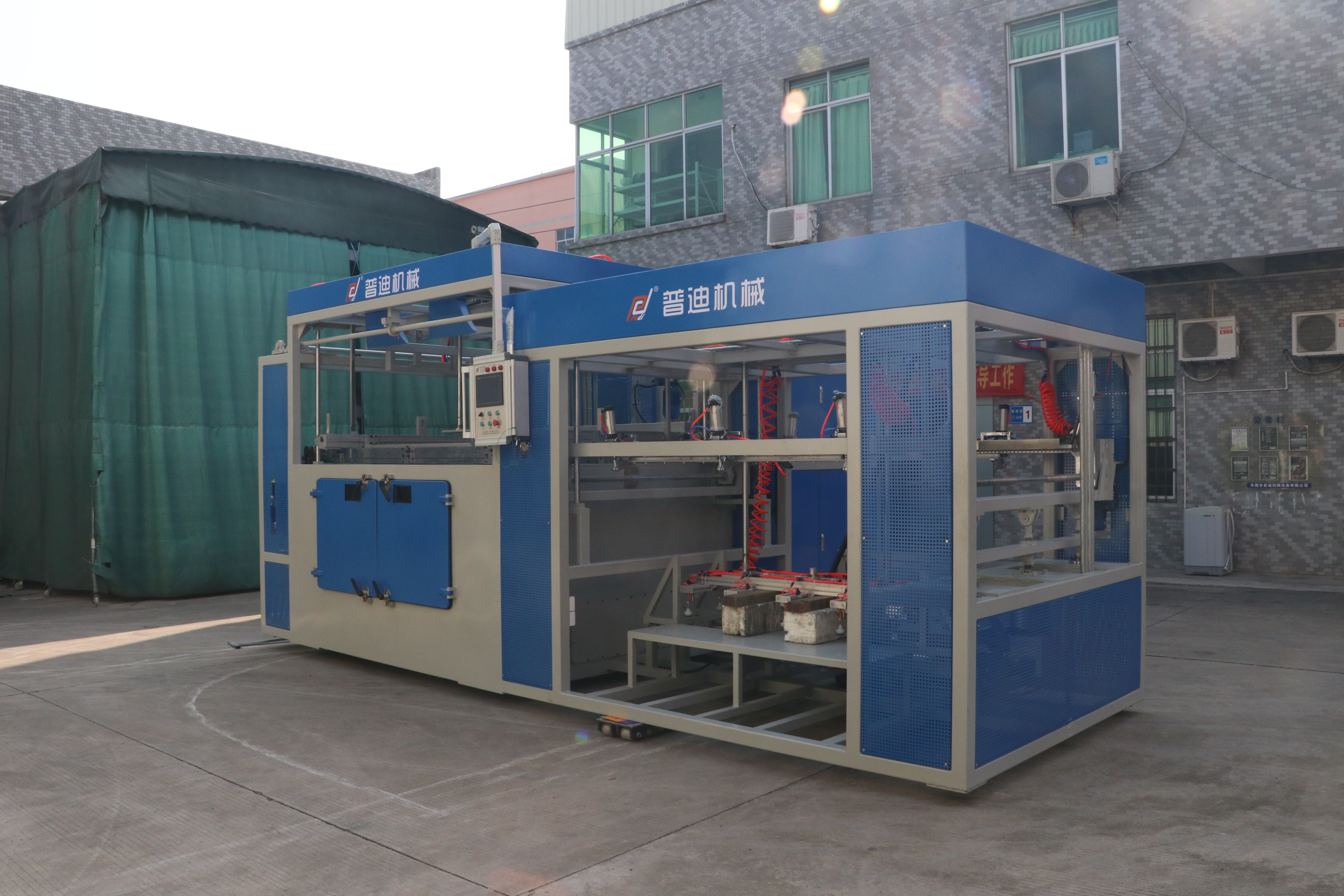

The multi-station rotary molding machine can produce all kinds of parts based on the different mold structure. It can also store lots of memories, so that it can be used fast and efficient to prevent waste in necessary. The machine’s design is geared towards minimizing material waste, thereby reducing material costs and promoting sustainability. Whether you are ready to buy or not, you can all contact with us, we will give you our professional knowledge.

Strong Storage:

The machine has multiple stations that can hold and process materials simultaneously, which increases the storage capacity of the machine, the design of the machine is to operate continuously, which means that it can process materials without interruption, thereby increasing the storage capacity of the machine. The most important is that it is equipped with an automated material handling system that can move materials between stations, which increases the storage capacity of the machine.

Product Parameter:

|

Maximum Forming Area |

1600mm*1600mm |

|

Forming Thickness |

0.4-1.5mm |

|

Product Forming Height |

180mm |

|

Furnace Length |

1650mm |

|

Total Power of Electric Furnace |

102KW |

|

Vacuum Pump |

5.5KW (with vacuum storage tank) |

|

Pulling Servo |

4.5KW |

|

Total Power |

120KW (normal use power: 40-60KW) |

|

Vacuum |

200m³/h |

|

Work Efficiency |

15-30s/mode (this parameter determines the length of time according to different product thicknesses) |

|

Total Air Source (external configuration) |

0.6-0.8Mpa |

|

Power Supply |

380V/50HZ (4+1 cable 50 m²) |

|

Rails |

Steel Girder |

|

Zipper Chain |

KMC Double Row B Chain (made in Taiwan) |

|

Main Frame |

Channel steel, steel plate, angle iron and stainless steel are national standards |

|

Body Sheet Metal |

Baking Paint and Electroplating Treatment |

|

Total Equipment Weight (reference) |

6.5T |

|

Machine Size (footprint area) |

10000mm*3000mm*2800mm |

The Maintenance for the Multi-station Rotary Molding Machine: