Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

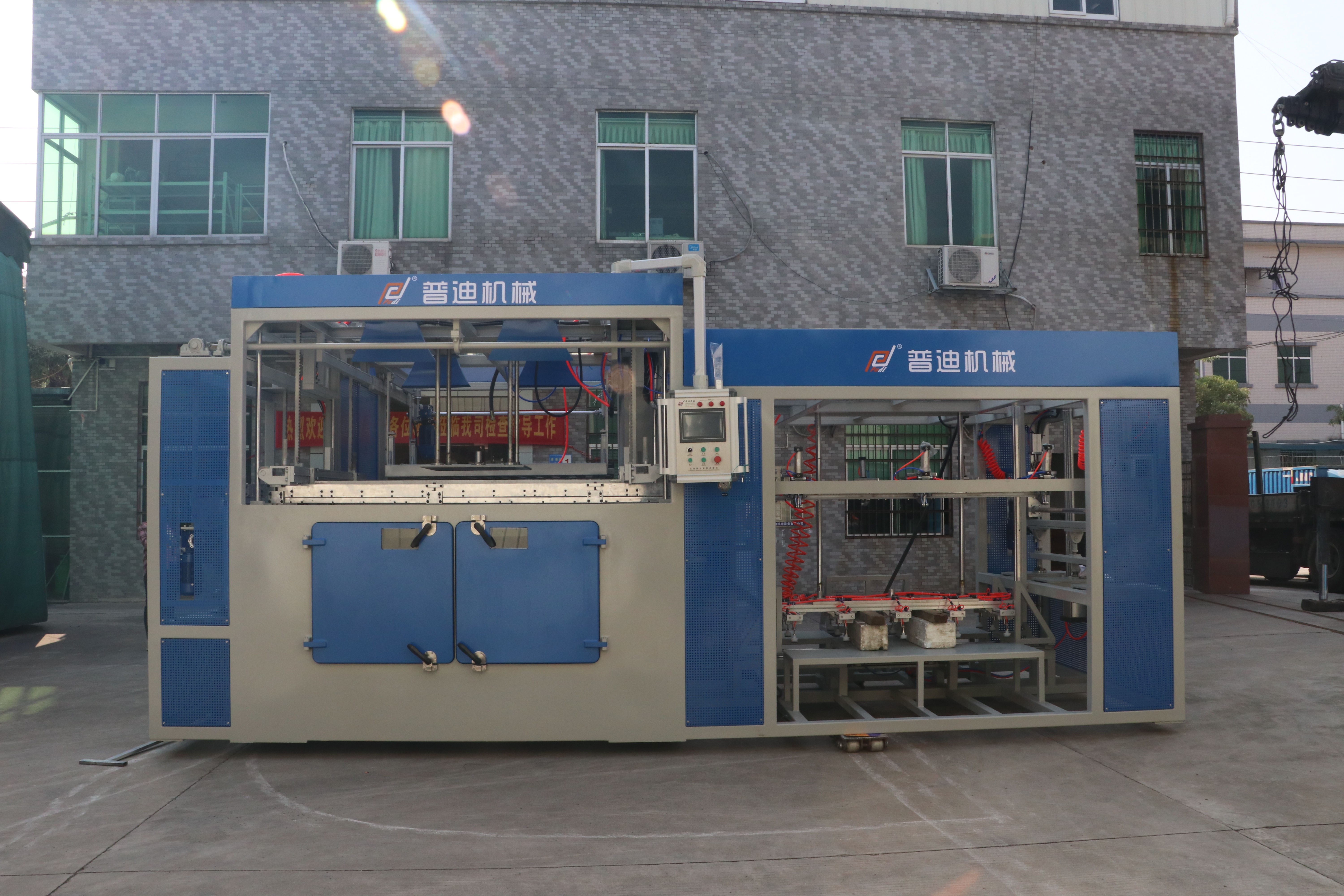

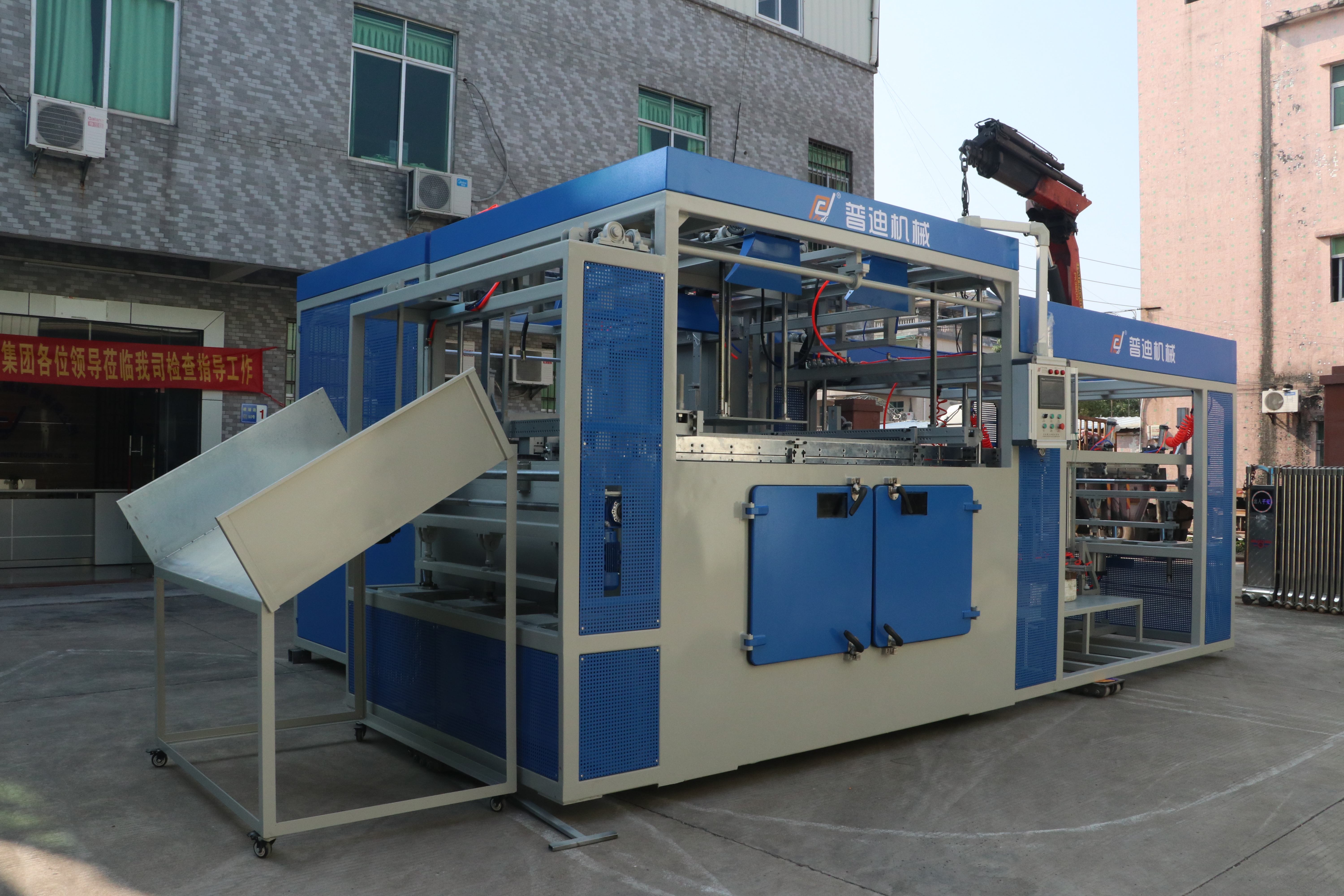

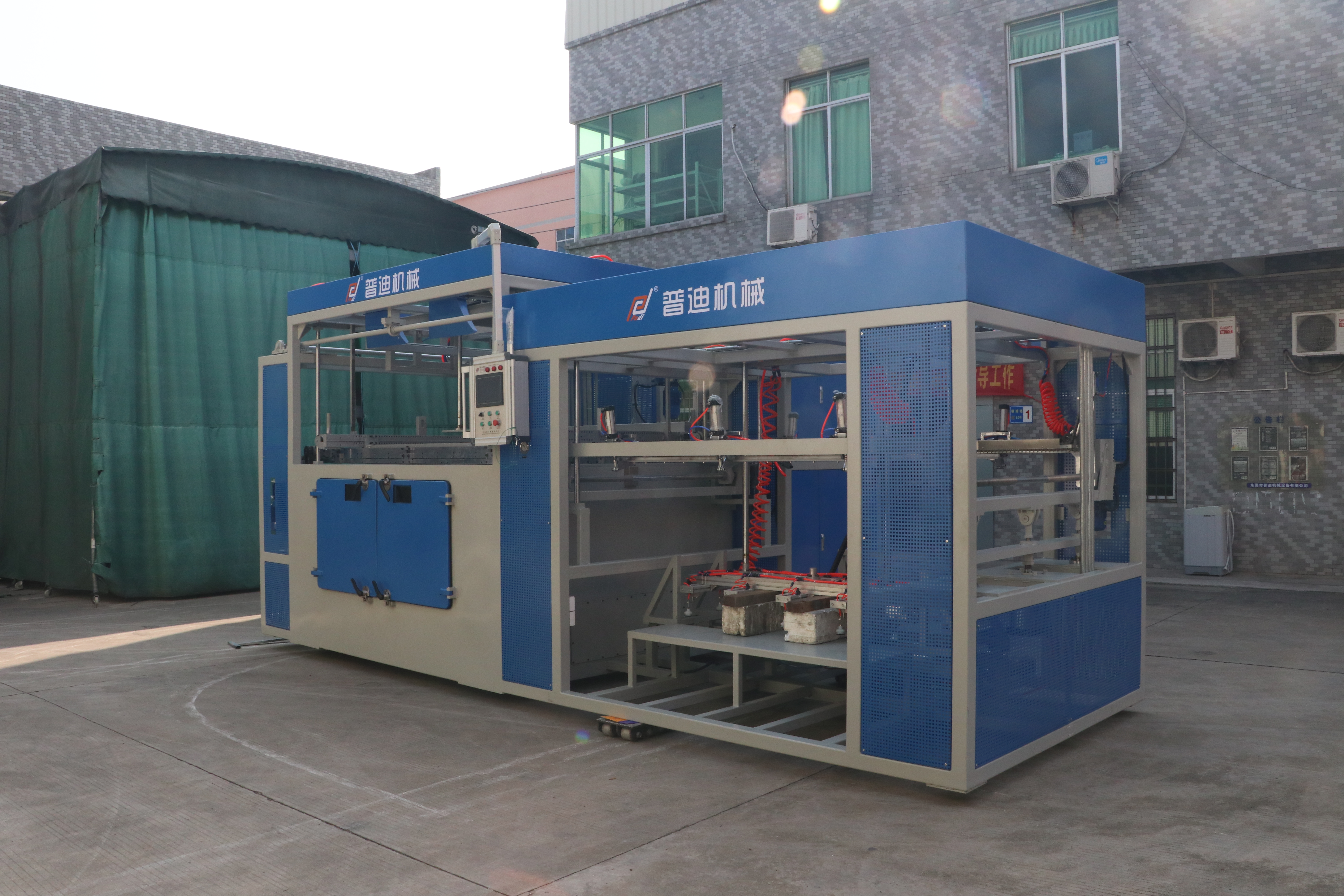

The all parameters and operation of the fully automatic loading and unloading vacuum thick sheet forming machine can be all set up in the touch screen, and you can freely change 2 different modes. Just heating with 5 minutes, you can start to manufacture the sheets with the energy-saving heating stick. The temperature control using regulator module mode, each heating element can be as a heating unit.

Convenient:

The machine is equipped with an automated loading and unloading system that eliminates the need for manual handling of the raw material and finished product. It can produce a high volume of formed products in a short amount of time, which increases production efficiency and reduces lead times. The operation to make it normally work is also very simple, you can just follow our steps to do.

Besides, the machine is capable of forming a wide range of products from different materials, which makes it a versatile solution for various industries, and you will know how useful with our machine with low cost!

Temperature Control:

The machine is also equipped with automatic features that simplify the vacuum forming process, such as automatic material feeding, heating, forming, and cooling. And it has the precise temperature sensors that monitor the temperature of the heating elements and the forming area.

The machine uses advanced heating elements that are capable of heating the material to the required temperature quickly and evenly. It is capable of automatically adjusting the temperature based on the material being used and the desired forming results.

Product Parameter:

|

Maximum Forming Area |

1600mm*1600mm |

|

Forming Thickness |

0.4-1.5mm |

|

Product Forming Height |

180mm |

|

Furnace Length |

1650mm |

|

Total Power of Electric Furnace |

102KW |

|

Vacuum Pump |

5.5KW (with vacuum storage tank) |

|

Pulling Servo |

4.5KW |

|

Total Power |

120KW (normal use power: 40-60KW) |

|

Vacuum |

200m³/h |

|

Work Efficiency |

15-30s/mode (this parameter determines the length of time according to different product thicknesses) |

|

Total Air Source (external configuration) |

0.6-0.8Mpa |

|

Power Supply |

380V/50HZ (4+1 cable 50 m²) |

|

Rails |

Steel Girder |

|

Zipper Chain |

KMC Double Row B Chain (made in Taiwan) |

|

Main Frame |

Channel steel, steel plate, angle iron and stainless steel are national standards |

|

Body Sheet Metal |

Baking Paint and Electroplating Treatment |

|

Total Equipment Weight (reference) |

6.5T |

|

Machine Size (footprint area) |

10000mm*3000mm*2800mm |