Understanding Plastic Sheet Shearing Machines: A Comprehensive Guide

Introduction

Plastic sheet shearing machines play a crucial role in various industries, offering efficient and precise cutting solutions for a wide range of applications. From manual to fully automatic machines, these tools provide manufacturers with the capability to cut plastic sheets with accuracy and speed, enhancing productivity and product quality. In this comprehensive guide, we will delve into the different types of plastic sheet shearing machines, their key features and components, and important factors to consider when choosing the right machine for your specific needs.

Types of Plastic Sheet Shearing Machines

Plastic sheet shearing machines come in different types, each with its own set of features, advantages, and applications.

Manual Machines:

Manual plastic sheet shearing machines are operated by hand, requiring the user to feed the plastic sheet through the cutting mechanism manually. These machines are simple in design and easy to operate, making them suitable for small-scale operations and workshops. They offer basic cutting functionality and are ideal for cutting thinner plastic sheets with moderate precision. However, they may not be suitable for high-volume production or cutting thicker materials due to limitations in cutting capacity and speed.

Semi-automatic Machines:

Semi-automatic plastic sheet shearing machines combine manual and automated features, offering improved efficiency and productivity compared to manual machines. These machines feature automated cutting mechanisms controlled by manual inputs from the operator. They provide higher cutting speeds and greater precision, making them suitable for mediumto large-scale production environments. Semi-automatic machines are versatile and can handle a wide range of plastic materials and thicknesses, making them popular choices for manufacturing facilities with diverse production requirements.

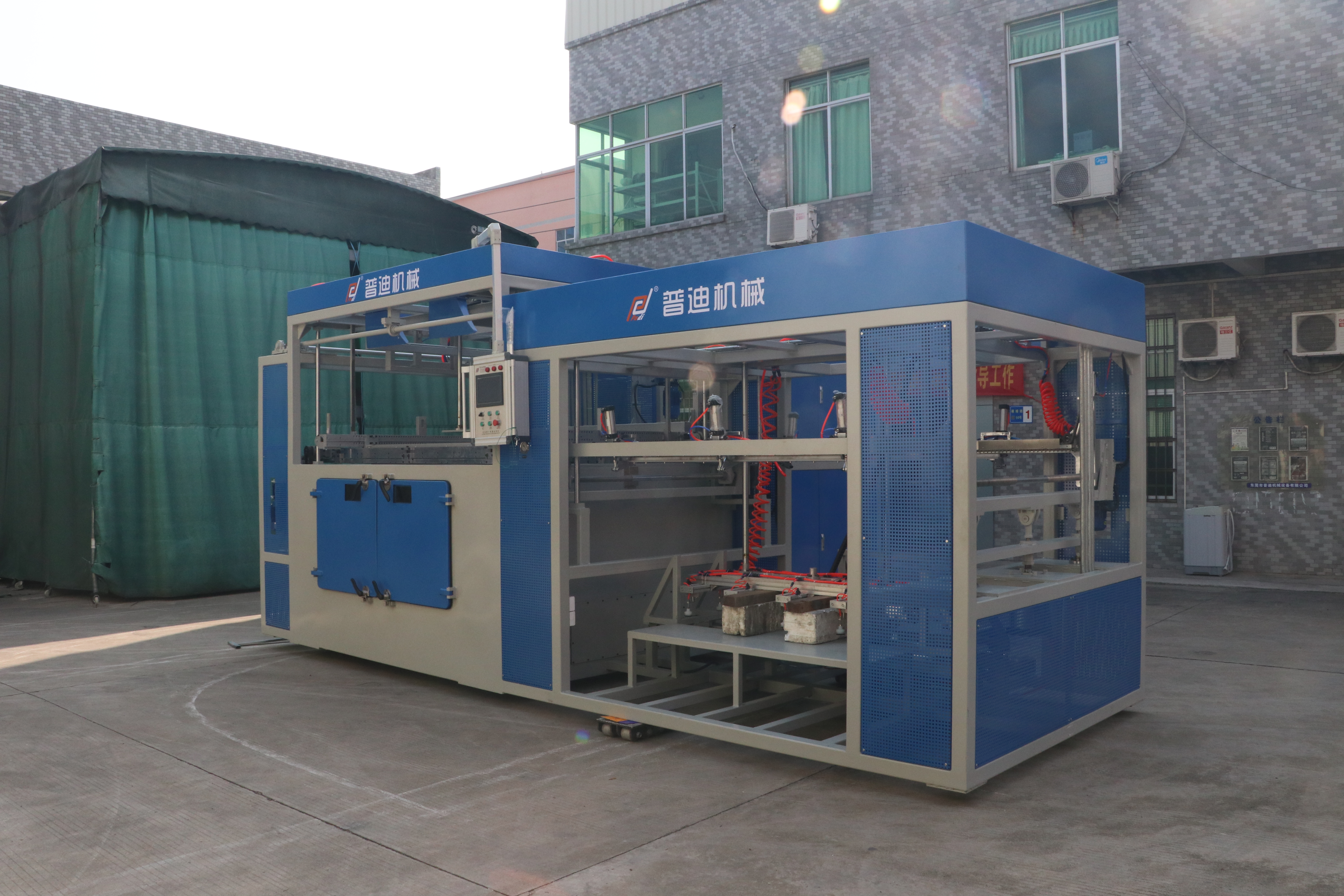

Fully automatic machines:

Fully automatic plastic sheet shearing machines are the most advanced and efficient type of shearing machine available on the market. These machines are fully automated, with cutting processes controlled by computerized systems and programmable parameters. They offer the highest levels of precision, speed, and productivity, making them ideal for high-volume production lines and large-scale manufacturing operations. Fully automatic machines can handle various plastic materials, thicknesses, and cutting requirements with ease, maximizing efficiency and reducing labor costs.

Key Features and Components

Plastic sheet shearing machines consist of several key features and components that contribute to their functionality and performance.

Blades:

The blades are one of the most critical components of a plastic sheet shearing machine. They are responsible for cutting the plastic sheet with precision and accuracy. Different types of blades are available for cutting various types of plastic materials and thicknesses. High-quality blades made from durable materials such as steel or carbide ensure long-lasting performance and optimal cutting results.

Cutting Mechanisms:

The cutting mechanism of a plastic sheet shearing machine determines how the cutting action is performed. Common cutting mechanisms include shear cutting, guillotine cutting, and rotary cutting. Shear cutting involves two blades moving past each other to cut the plastic sheet, while guillotine cutting uses a single blade to make a straight downward cut. Rotary cutting involves a rotating blade that cuts through the plastic sheet in a continuous motion. The choice of cutting mechanism depends on the specific cutting requirements and the type of plastic material being processed.

Controls:

The controls of a plastic sheet shearing machine allow the operator to manage and adjust various cutting parameters, such as cutting speed, pressure, and blade positioning. Manual machines typically have basic manual controls, while semi-automatic and fully automatic machines feature more advanced automated controls. Automated controls offer greater precision and consistency in cutting results, reducing the risk of errors and improving overall productivity.

Safety Features:

Safety is paramount when operating a plastic sheet shearing machine. These machines are equipped with various safety features to protect operators from potential hazards during operation. Common safety features include blade guards, emergency stop systems, and safety interlocks. Blade guards prevent operators from coming into contact with the cutting blades, while emergency stop systems allow for immediate shutdown of the machine in case of an emergency. Safety interlocks ensure that the machine cannot be operated unless all safety guards and covers are securely in place, reducing the risk of accidents and injuries.

Automation Capabilities:

Automation capabilities play a significant role in the efficiency and productivity of plastic sheet shearing machines. Fully automatic machines are equipped with advanced automation features, such as CNC (computer numerical control) systems and programmable cutting parameters. These automation capabilities allow for precise control of cutting processes, minimizing material waste, and maximizing production throughput. Additionally, automation reduces the need for manual intervention, leading to improved consistency and quality in cutting results.

Factors to Consider When Choosing a Plastic Sheet Shearing Machine

When selecting a plastic sheet shearing machine for your manufacturing operation, several factors should be taken into consideration to ensure that you choose the right machine for your specific needs.

Cutting Capacity:

The cutting capacity of a plastic sheet shearing machine refers to the maximum thickness and size of plastic sheets that the machine can effectively cut. It is essential to choose a machine with sufficient cutting capacity to accommodate the size and thickness of the plastic materials used in your production processes. Consider the maximum cutting length and thickness specifications of the machine to ensure compatibility with your specific cutting requirements.

Material Compatibility:

Different plastic materials have varying properties and characteristics that can affect the cutting process. When selecting a plastic sheet shearing machine, consider the types of plastic materials you will be working with and ensure that the machine is compatible with those materials. Some machines may be specifically designed for cutting certain types of plastics, while others may offer more versatility and compatibility with a wider range of materials.

Precision:

Precision is critical in plastic sheet-cutting applications, especially when working with intricate shapes and designs. Choose a machine that offers high levels of precision in cutting to ensure accurate and consistent results. Look for machines with advanced cutting mechanisms and control systems that allow for precise control of cutting parameters, such as cutting speed, pressure, and blade positioning. Additionally, consider the repeatability of the machine's cutting capabilities to ensure consistent performance over time.

Speed:

The cutting speed of a plastic sheet shearing machine determines how quickly it can process plastic materials and produce finished products. Higher cutting speeds can significantly impact productivity and throughput in manufacturing operations. When choosing a machine, consider the required production output and select a machine with a cutting speed that meets your production requirements. However, it is essential to balance cutting speed with precision and quality to ensure optimal cutting results.

Cost:

The cost of a plastic sheet shearing machine is a significant investment for any manufacturing operation. Consider the initial purchase price as well as the ongoing operational costs when evaluating different machine options. While it may be tempting to opt for the cheapest machine available, it is essential to consider the long-term value and performance of the machine. Choose a machine that offers the best combination of features, performance, and affordability to maximize the return on investment for your business.

Conclusion

Plastic sheet shearing machines are indispensable tools in the manufacturing industry, offering efficient and precise cutting solutions for a wide range of applications. Whether you're cutting thin plastic sheets for packaging or thick plastic materials for construction, there is a plastic sheet shearing machine available to meet your specific needs. By understanding the different types of machines, their key features and components, and important factors to consider when choosing a machine, you can make an informed decision that will enhance productivity, quality, and profitability in your manufacturing operation.