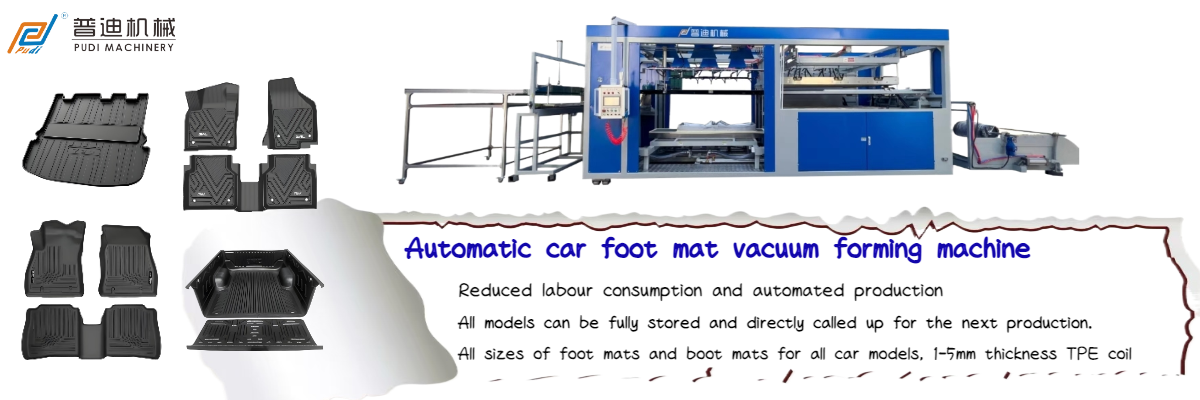

High-Efficiency Automatic Car Foot Mat & Trunk Mat Vacuum Forming Machine

Introduction: The automotive industry continues to evolve at a rapid pace, driving up the demand for advanced manufacturing processes. One standout innovation is the Automatic Car Foot Mat & Trunk Mat Vacuum Forming Machine, designed to streamline production of high-quality foot mats and trunk mats. In this blog post, we’ll explore its core advantages, discuss how automatic feeding, heating, vacuum forming, and cutting processes work together, and highlight the critical role this equipment plays in ensuring efficiency and precision.

1. Automatic Feeding for Consistent Quality

One of the most notable features of next-generation vacuum forming machines is the automatic feeding system. By automating the process of delivering raw sheet materials such as TPE, PVC, or other thermoplastics into the machine, manual intervention is minimized. This not only improves the accuracy and repeatability of each production cycle but also frees up manpower for higher-level tasks. Additionally, automatic feeding ensures consistent quality, making it an essential component for mass production of car foot mats and trunk mats.

2. Optimal Heating for Forming Precision

Once the materials are automatically fed and positioned, heating takes center stage. High-precision heating units uniformly raise the temperature of the thermoplastic sheets, ensuring that every inch of the material is heated to an ideal temperature. Proper heating is critical to achieving the right flexibility and formability, which ultimately determines the detail, texture, and strength of the mold. This precision heating mechanism guarantees that foot mats and trunk mats conform seamlessly to the design, resulting in a visually appealing and structurally robust final product.

3. Vacuum Forming for Intricate Detailing

After heating, the core process known as vacuum forming begins. The heated sheet is molded over a meticulously designed fixture that outlines the exact shape of a foot mat or trunk mat. The vacuum pressure ensures that every crease, contour, and edge is accurately rendered, making the product fit perfectly in a car’s interior. This method also ensures a uniform thickness ranging from 1 to 5 mm, commonly used for TPE coils in automotive mats, offering enhanced durability and wear resistance.

4. Precision Cutting for Clean Edges

A critical final step is the cutting process. Equipped with state-of-the-art cutting tools, the vacuum forming machine neatly trims excess material to deliver the finished foot mats and trunk mats with clean edges. This precision cutting capability consistently meets the dimensional requirements of manufacturers, guaranteeing an excellent fit whether for driver seats, passenger seats, or trunk areas.

5. Advantages of an Automated Production Line

The synergy of automatic feeding, heating, vacuum forming, and cutting drives remarkable advantages:

- Reduced Labor Costs: Automation handles repetitive tasks, so production teams can focus on quality checks and continuous improvements.

- Faster Turnaround: Automated processes significantly cut down the time required for each production cycle, enabling manufacturers to cater to bulk orders rapidly.

- Lower Scrap Rates: Precision in every stage of the process translates to minimal waste, which is both cost-effective and eco-friendly.

- Consistent Output: Uniform quality across batches ensures that every car owner experiences the same high-quality floor mats and trunk liners.

6. Machine Application in Today’s Automotive Industry

From budget sedans to premium SUVs, an Automatic Car Foot Mat & Trunk Mat Vacuum Forming Machine supports various designs and dimensions. As vehicle personalization becomes more popular, manufacturers require scalable and flexible production that suits diverse customization needs. This machine empowers businesses to produce tailored foot mats for different car brands efficiently, meeting consumer demands without compromising on quality.

Conclusion

The full-automatic car foot mat and trunk mat vacuum forming machine holds immense promise for manufacturers seeking to enhance quality, reduce labor costs, and accelerate production timelines. By combining automatic feeding, precise heating, vacuum forming, and cutting, businesses can deliver top-tier car mat products with unparalleled consistency and accuracy.

For more information on how to streamline your automotive production, visit Dongguan Pudi Machinery Equipment Co., Ltd. Our team specializes in R&D, design, manufacturing, sales, and service of vacuum forming solutions. You can reach us by phone at +86 15920606802, email at qinhe@dgpudi.com, or explore our full range of offerings on our official website: http://www.pudimachinery.com.