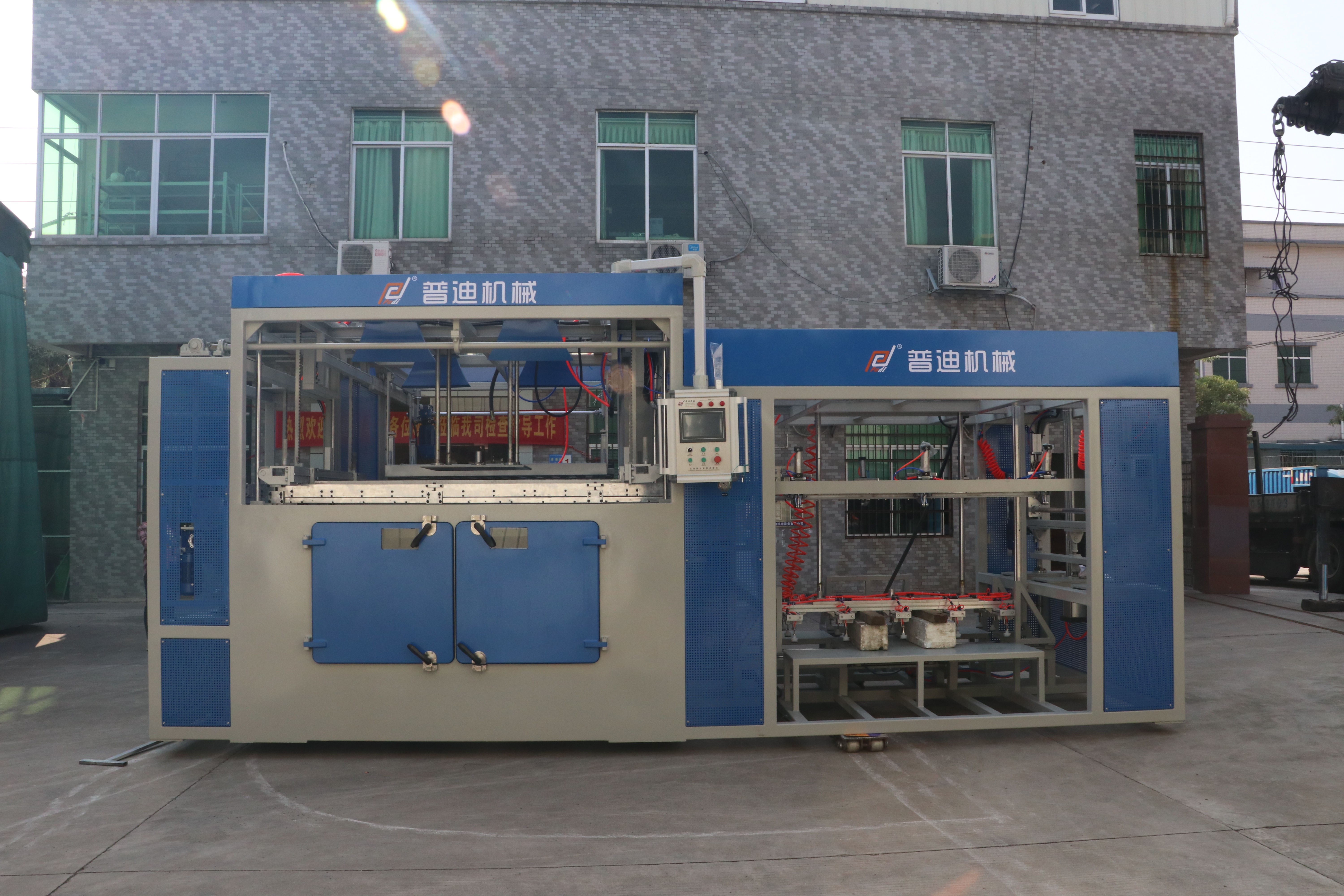

The World of Plastic Sheet Forming Machines: A Closer Look at Wholesale Plastic Sheet Forming Machine Manufacturers

In the world of manufacturing, plastic stands as one of the most versatile and widely used materials. From household items to industrial components, its applications span countless industries. A critical stage in plastic production is the shaping and forming of plastic sheets—a process enabled by specialized machinery. This blog explores the role of wholesale plastic sheet forming machine manufacturers, diving into how these machines work, their types, and their significance in modern manufacturing.

What Is a Plastic Sheet Forming Machine?

A plastic sheet forming machine is equipment designed to mold plastic sheets into specific shapes. The process typically involves:

- Heating plastic sheets to a pliable state.

- Shaping the softened material using molds, pressure, or vacuum suction.

- Cooling and trimming the final product.

Common types include:

- Thermoforming Machines: Use heat and pressure to shape plastic.

- Vacuum Forming Machines: Rely on vacuum suction to draw plastic into molds.

These machines excel in high-volume production, making them indispensable for industries like packaging, automotive, and medical supplies.

The Role of Wholesale Manufacturers

Wholesale plastic sheet forming machine manufacturers are pivotal in the supply chain. Their responsibilities extend beyond production to include:

- Customization: Tailoring machines to meet industry-specific needs (e.g., food-safe molds for packaging).

- Cost Efficiency: Offering bulk pricing to reduce capital expenditure for businesses.

- Technical Support: Providing maintenance, training, and troubleshooting services.

By serving both small businesses and large enterprises, these manufacturers ensure accessibility to advanced forming technologies across scales.

How Do Plastic Sheet Forming Machines Work?

The process can be broken into five key steps:

- Feeding: Plastic sheets (e.g., polyethylene or polystyrene) are loaded into the machine.

- Heating: The sheet is heated to a malleable temperature using elements or hot air.

- Shaping:

- Thermoforming: Air pressure or mechanical presses force the plastic into molds.

- Vacuum Forming: A vacuum pulls the sheet onto a mold surface.

- Cooling & Trimming: The formed plastic is cooled, solidified, and trimmed to remove excess material.

- Quality Control: Products are inspected for defects before finishing (e.g., painting or drilling).

This automated workflow enables rapid, consistent production with minimal waste.

Types of Plastic Sheet Forming Machines

Types of Plastic Sheet Forming Machines

| Machine Type | Key Features | Common Applications |

|---|---|---|

| Thermoforming | High-speed, ideal for shallow molds | Food containers, blister packaging |

| Vacuum Forming | Cost-effective for intricate shapes | Automotive parts, display trays |

| Pressure Forming | Combines heat and pressure for precision | Medical devices, aerospace components |

| Roll Forming | Creates continuous profiles via rollers | Plastic roofing, gutters |

| Injection Molding | Melts and injects plastic into molds (not sheet) | Small components (e.g., bottle caps) |

Each type caters to specific material properties, product geometries, and production volumes.

Why Wholesale Machines Matter

- Scalability: Enables businesses to ramp up production without prohibitive costs.

- Innovation: Manufacturers integrate advancements like energy-efficient heating and AI-driven quality checks.

- Supply Chain Stability: Reliable access to machinery minimizes production downtime.

- Global Competitiveness: Affordable, high-quality machines help manufacturers stay competitive in international markets.

Conclusion

Plastic sheet forming machines are the backbone of countless industries, transforming raw materials into everyday essentials. Wholesale manufacturers bridge the gap between innovation and practicality, ensuring businesses of all sizes can leverage cutting-edge technology. Whether producing medical equipment or consumer packaging, these machines—and the companies behind them—are catalysts for efficiency, creativity, and growth.

By partnering with trusted manufacturers, businesses not only streamline production but also contribute to a future where plastic is shaped smarter, faster, and more sustainably.

Next time you encounter a plastic product, remember the intricate machinery and expertise that brought it to life.