Tabletop Vacuum Forming Machine: Revolutionizing Manufacturing Processes

In recent years, the tabletop vacuum forming machine has gained immense popularity in various industries due to its efficiency and effectiveness in molding and shaping materials. This innovative technology has revolutionized the manufacturing process by providing a cost-effective and time-saving solution for producing high-quality prototypes and small-scale production items. In this article, we will explore the different applications, benefits, and components of a tabletop vacuum forming machine.

1. Understanding Vacuum Forming?

Before delving into the specifics of a tabletop vacuum forming machine, it is crucial to understand the vacuum forming process itself. Vacuum forming is a technique used to shape various types of materials, such as plastic, wood, and metal, into specific forms using a mold. The process involves heating the chosen material until it becomes pliable, placing it over a mold, and then using vacuum pressure to force the material to conform to the mold's shape.

2. The Advantages of a Tabletop Vacuum Forming Machine?

2.1 Cost-Effectiveness:

Tabletop vacuum forming machines are significantly more cost-effective compared to their larger industrial counterparts. They offer a viable solution for small businesses, entrepreneurs, and hobbyists who have budget constraints. These machines allow for in-house production, eliminating the need for outsourcing, hence reducing costs in the long run.

2.2 Versatility:

Tabletop vacuum forming machines are incredibly versatile, capable of forming various materials, including thermoplastics, foam, and composite materials. Their adaptability makes them suitable for a wide range of applications such as packaging, signage, automotive components, and even cosplay accessories.

2.3 Speed and Efficiency:

These machines are designed to operate swiftly, providing quick turnaround times for projects. Additionally, tabletop vacuum forming machines have efficient heating elements and powerful vacuum systems that ensure consistent and precise molding, making them ideal for producing high-quality prototypes or small-scale production items.

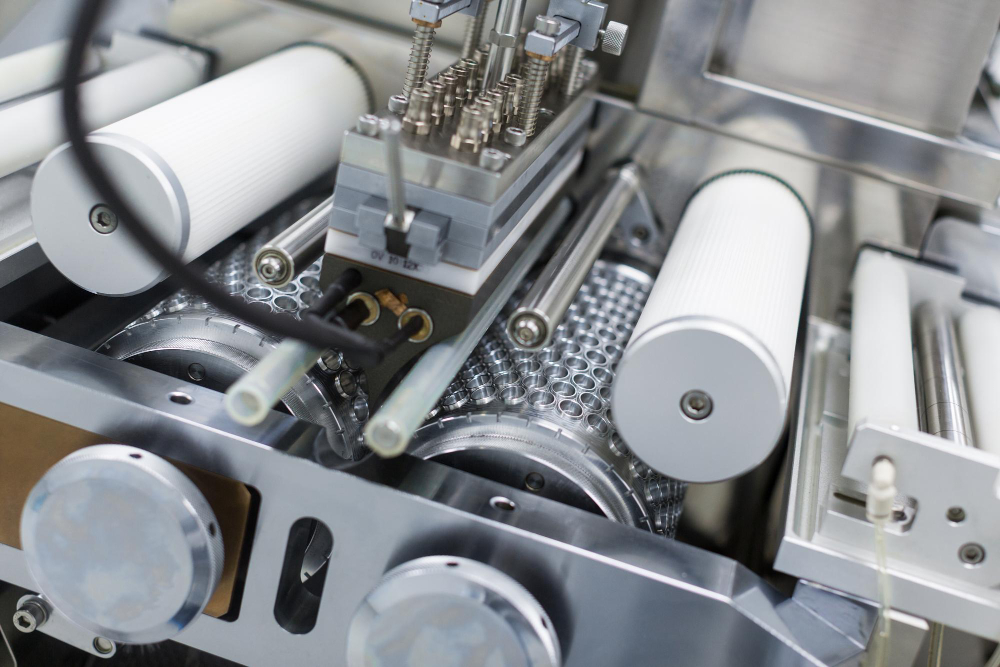

3. Key Components of a Tabletop Vacuum Forming Machine?

3.1 Heating Element:

The heating element is one of the primary components of a tabletop vacuum forming machine. It is responsible for heating the chosen material until it reaches its malleable state. Often, these machines employ infrared or quartz heating elements due to their rapid and uniform heat distribution.

3.2 Mold or Forming Surface:

The mold or forming surface is crucial as it determines the final shape and dimensions of the formed material. Tabletop vacuum forming machines allow for the use of pre-made molds, which can be easily attached and interchanged based on the desired shape. These molds are typically made of aluminum or composite materials for durability and heat resistance.

3.3 Vacuum Press:

The vacuum press is a critical component that enables the material to conform to the mold's shape. This component creates a vacuum environment by removing air or gases from beneath the material, allowing atmospheric pressure to shape the material uniformly. The vacuum press also ensures that the material is tightly secured during the cooling process.

4. Applications of a Tabletop Vacuum Forming Machine?

4.1 Packaging Industry:

The tabletop vacuum forming machine finds extensive application in the packaging industry. It enables the production of custom-shaped packaging materials, such as blister packs and clamshells, that are both visually appealing and protective of the product.

4.2 Prototyping:

One of the most significant advantages of tabletop vacuum forming machines is their ability to create prototypes rapidly and cost-effectively. This makes them popular among designers, engineers, and product developers who require functional prototypes before moving to large-scale manufacturing.

4.3 Education and DIY Projects:

Tabletop vacuum forming machines are widely used in educational settings, allowing students to explore the manufacturing process hands-on. Additionally, these machines have gained popularity among hobbyists and DIY enthusiasts who create various crafts and accessories, such as custom phone cases or cosplay props.

Tabletop Vacuum Forming Machine Is Easy to Use

The tabletop vacuum forming machine has transformed the manufacturing industry by providing an accessible and efficient solution for molding materials. From its cost-effectiveness and versatility to its speed and efficiency, this technology has proven to be invaluable in various industries. As advancements continue to be made, tabletop vacuum forming machines will undoubtedly play a pivotal role in reshaping the way we manufacture products in the future.