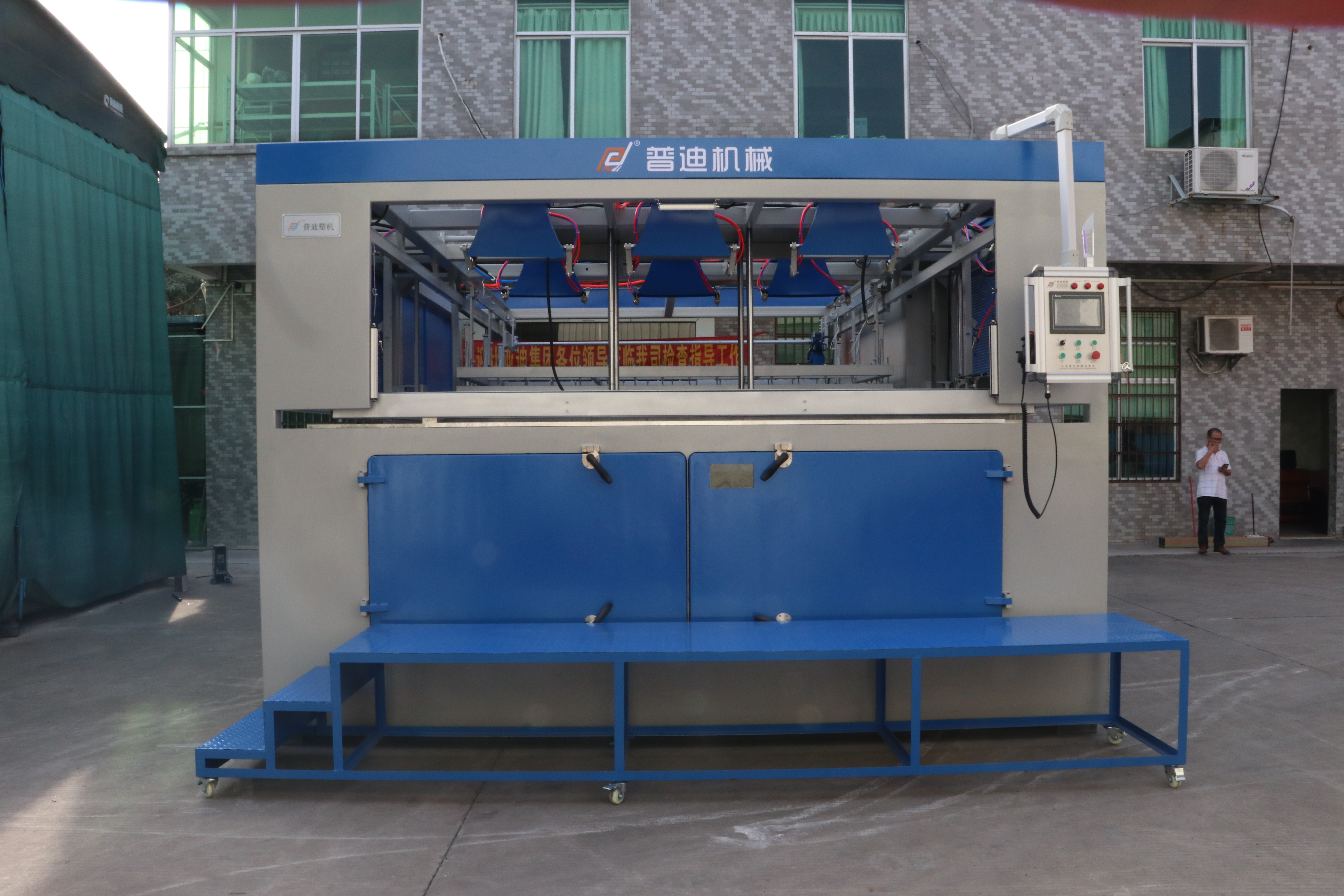

Styrofoam Box Vacuum Forming Machine - Revolutionizing Packaging Solutions

In the world of packaging and product manufacturing, the utilization of advanced technology has become a game-changer. Among the various innovative machines revolutionizing the industry, the Styrofoam Box Vacuum Forming Machine stands out as a cutting-edge solution for creating customized, high-quality packaging materials. This powerful machine combines precision engineering with efficiency, enabling businesses to meet the growing demand for sustainable and visually appealing packaging solutions. In this blog post, we will delve into the functionalities, benefits, and applications of the Styrofoam Box Vacuum Forming Machine, highlighting its significance in the packaging industry.

The Evolution of Packaging Technology:

Packaging has always been an essential aspect of product manufacturing, serving not only as a protective layer but also as a means of branding and marketing. Over the years, the packaging industry has witnessed significant advancements in technology, with the introduction of automated machines reshaping the way products are packaged and presented to consumers. One such technological innovation that has gained widespread popularity is the Styrofoam Box Vacuum Forming Machine.

Understanding Vacuum Forming Technology:

At the core of the Styrofoam Box Vacuum Forming Machine lies the vacuum forming technology, a process that involves heating a sheet of plastic material until it becomes pliable and then molding it into a specific shape using vacuum pressure. This process allows manufacturers to create customized packaging solutions that are not only durable and cost-effective but also visually appealing. The versatility of vacuum forming technology enables businesses to design packaging materials that cater to their unique requirements, ensuring optimal protection and presentation of their products.

Benefits of Styrofoam Box Vacuum Forming Machine:

-

Customization:

One of the key benefits of the Styrofoam Box Vacuum Forming Machine is its ability to create highly customized packaging solutions. Whether it's embossed logos, unique shapes, or tailored sizes, this machine provides businesses with the flexibility to design packaging materials that align with their brand identity and product specifications. -

Cost-Efficiency:

By utilizing vacuum forming technology, businesses can significantly reduce their packaging costs. The process is less labor-intensive compared to traditional packaging methods, resulting in faster production times and lower material wastage. This cost-efficiency translates to savings for businesses in the long run, making the Styrofoam Box Vacuum Forming Machine a worthwhile investment. -

Sustainability:

In today's environmentally conscious market, sustainability has become a top priority for businesses across industries. The Styrofoam Box Vacuum Forming Machine offers a sustainable packaging solution by using recyclable materials and minimizing the environmental impact of packaging production. This eco-friendly approach not only resonates with consumers but also positions businesses as responsible stewards of the environment.

Applications of Styrofoam Box Vacuum Forming Machine:

The versatility of the Styrofoam Box Vacuum Forming Machine extends to a wide range of industries and applications. From food packaging to electronic components, this machine can accommodate various product types and shapes, making it a versatile solution for businesses of all sizes. Some common applications of the Styrofoam Box Vacuum Forming Machine include:

- Food Industry: Packaging for fresh produce, meat, seafood, and baked goods.

- Electronics Industry: Protective packaging for electronic devices and components.

- Medical Industry: Custom trays and containers for medical supplies and equipment.

- Retail Industry: Display packaging for cosmetics, toys, and other consumer goods.

Conclusion:

The Styrofoam Box Vacuum Forming Machine represents a significant advancement in the packaging industry, offering businesses a powerful tool to enhance their packaging solutions. With its ability to create customized, cost-effective, and sustainable packaging materials, this machine has become a staple in modern manufacturing processes. As consumer preferences evolve and sustainability takes center stage, the Styrofoam Box Vacuum Forming Machine is poised to play a crucial role in shaping the future of packaging technology. Embracing this innovative machine can pave the way for businesses to stand out in the market, elevate their brand presence, and meet the growing demand for premium packaging solutions.