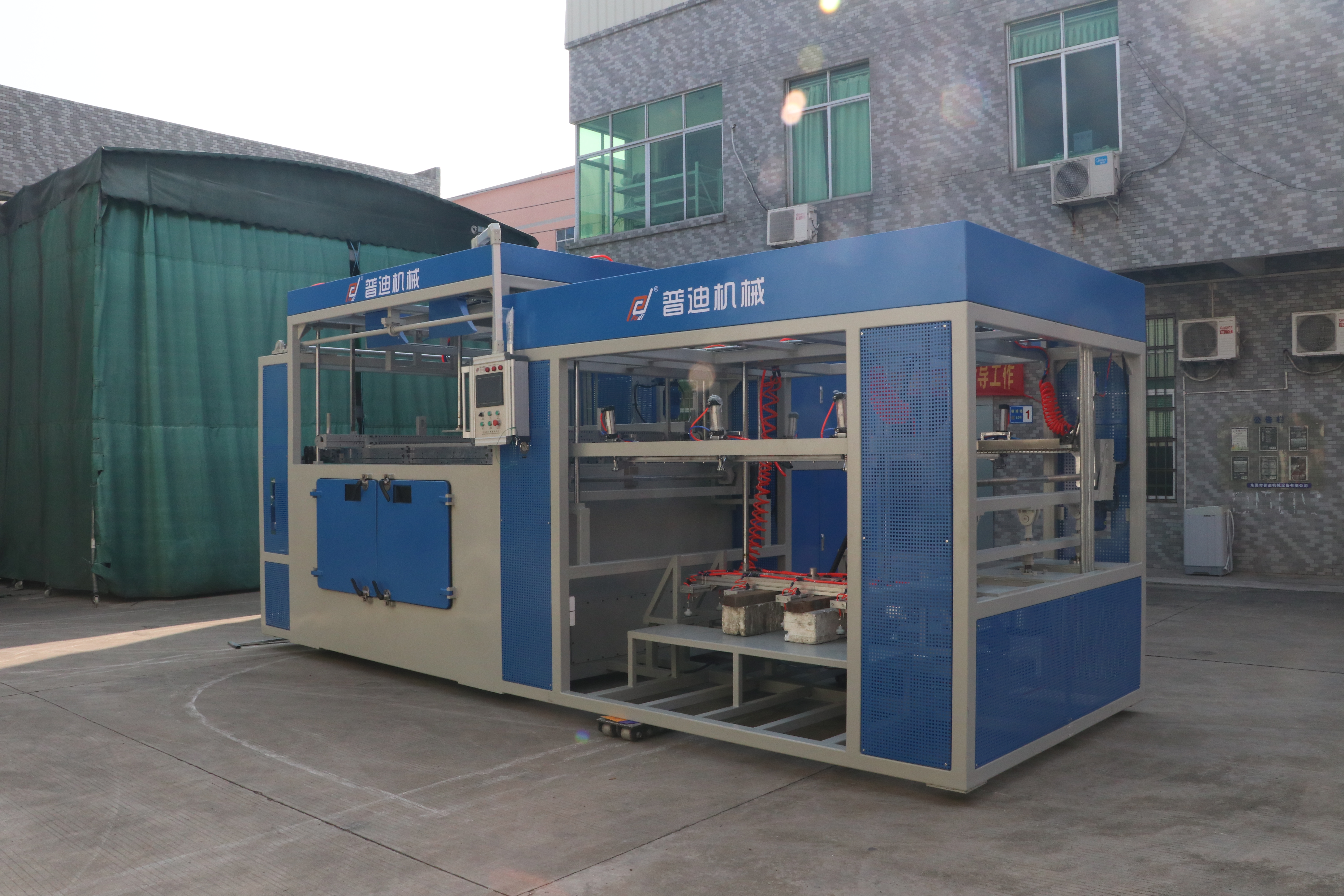

Large Vacuum Forming Machine for Sale - The Perfect Solution for Your Product Development Needs

When it comes to product development, having the right equipment is crucial. A large vacuum forming machine is a versatile and cost-effective solution that can meet the demands of various industries. In this article, we will explore the features, benefits, and applications of a large vacuum forming machine for sale. Whether you're a manufacturer, entrepreneur, or designer, this machine can revolutionize your production process and enhance your organization's efficiency.

1. The Scope of Large Vacuum Forming Machines?

- Understanding Vacuum Forming: Vacuum forming is a manufacturing process that involves heating a sheet of plastic and then stretching it over a mold or pattern. A large vacuum forming machine utilizes this technique on a larger scale, catering to projects that require larger molds or patterns.

- Ideal for Large-Scale Production: With a large vacuum forming machine, you can produce large quantities of plastic parts and components with ease. It is perfect for industries such as automotive, aerospace, medical, and packaging.

2. Features of a Large Vacuum Forming Machine?

- Robust Construction: These machines are built with high-quality materials, ensuring durability and longevity.

- Efficient Heating System: Equipped with advanced heating elements, large vacuum forming machines offer precise temperature control, allowing for consistent and uniform heating of the plastic sheets.

- Customizable Molds: The machine's bed can accommodate various sizes and shapes of molds, enabling you to create diverse products.

- Automatic Cooling System: The cooling system ensures that the formed plastic parts cool down rapidly, enabling quicker production cycles.

3. Benefits of Investing in a Large Vacuum Forming Machine?

- Cost-Effective Manufacturing: Vacuum forming is a cost-effective plastic manufacturing process. By choosing a large vacuum forming machine, you can significantly reduce production costs compared to other methods such as injection molding or CNC machining.

- Versatility in Material Selection: Large vacuum forming machines can handle a wide range of thermoplastic materials, including ABS, PVC, PETG, and polycarbonate. This versatility allows you to adapt to specific product requirements.

- Rapid Prototyping: A large vacuum forming machine allows for quick and precise prototyping, reducing time-to-market for new products. This speed and flexibility contribute to staying ahead of the competition.

- Enhanced Design Possibilities: The ability to easily create complex shapes and forms opens up new design possibilities. The large working area of the machine enables the production of large and intricate parts that were previously challenging to achieve.

4. Applications of Large Vacuum Forming Machines?

- Automotive Industry: Large vacuum forming machines are used to manufacture interior and exterior parts such as dashboards, door panels, and bumpers.

- Aerospace Industry: From aircraft interior components to protective covers, vacuum forming plays a significant role in the production of lightweight and durable materials for aircraft.

- Medical Field: Vacuum-formed medical devices, equipment enclosures, and protective casings are produced using large vacuum forming machines.

- Packaging Industry: Large vacuum forming machines are used to create packaging trays, blister packs, and other packaging solutions for various consumer products.

Investing Large Vacuum Forming Machine Greatly Improve Manufacturing Ability

Investing in a large vacuum forming machine can significantly improve your product development and manufacturing capabilities. With its versatility, cost-effectiveness, and ability to produce large quantities of plastic parts, this machine is a valuable asset for any industry. Whether you're a small business or a large-scale manufacturer, our large vacuum forming machine for sale can revolutionize your production process and take your organization to new heights.