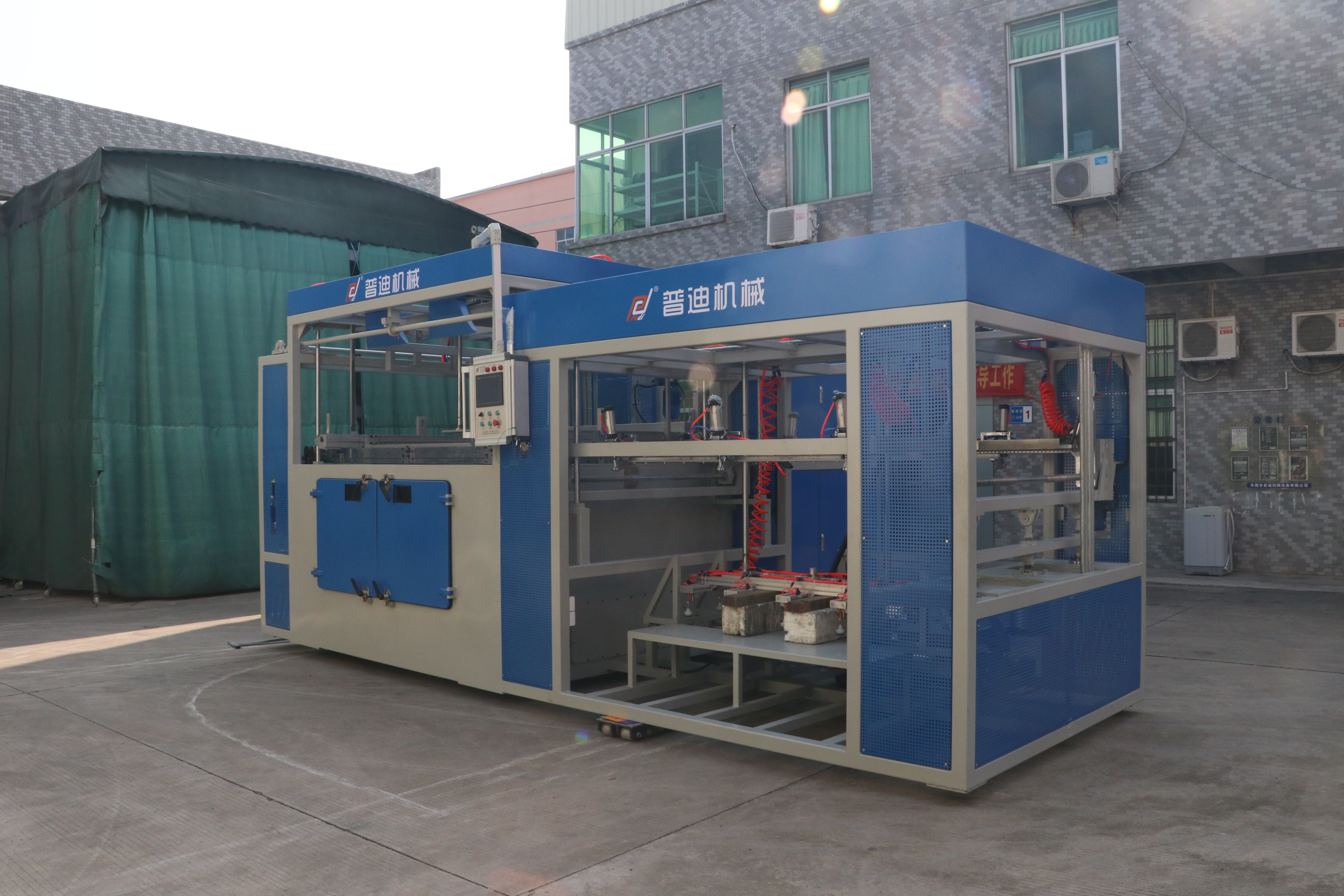

How do multi-station thermoforming machines boost efficiency in packaging production?

In the fast-paced world of packaging manufacturing, efficiency is key. Manufacturers are constantly seeking ways to streamline their operations, reduce costs, and meet the growing demands of their customers. One technology that has proven to be a game-changer is the multi-station thermoforming machine. This blog post will explore how these machines can significantly increase production efficiency for packaging manufacturers.

1. Increased Throughput:

The primary advantage of multi-station thermoforming machines is their ability to increase throughput. Unlike single-station machines that can only produce one product at a time, multi-station machines can simultaneously work on several products, significantly increasing the output.

2. Reduced Labor Costs:

By automating the production process, multi-station thermoforming machines reduce the need for manual labor. This not only cuts down on labor costs but also minimizes the risk of human error, leading to a more consistent and higher quality product.

3. Improved Quality Control:

These machines come equipped with advanced quality control systems that ensure each product meets the required standards. This results in fewer defects and less waste, further enhancing efficiency.

4. Energy Efficiency:

Multi-station thermoforming machines are designed to be energy-efficient. They consume less power compared to single-station machines, leading to significant cost savings over time.

5. Customization and Flexibility:

One of the most significant benefits of these machines is their ability to produce a wide range of products. This flexibility allows manufacturers to cater to diverse customer needs without compromising on efficiency.

6. Reduced Downtime:

Multi-station machines are designed for minimal downtime. They can run continuously for extended periods, ensuring a steady flow of production. This is particularly beneficial during peak seasons when demand is high.

7. Scalability:

As a manufacturer's needs grow, so can their use of multi-station thermoforming machines. These machines can be easily scaled up to meet increasing production demands, providing a sustainable solution for growth.

Conclusion:

In conclusion, multi-station thermoforming machines offer numerous benefits to packaging manufacturers, including increased throughput, reduced labor costs, improved quality control, energy efficiency, customization, reduced downtime, and scalability. By incorporating this technology into their production process, manufacturers can significantly boost their efficiency and stay ahead in the competitive packaging industry.