Enhancing Manufacturing Efficiency with the Plastic Sheet Press Machine

Efficiency reigns supreme in the ever-changing landscape of manufacturing. The success of a product heavily depends on every phase, from its initial design to final production. Among the array of tools and technologies that drive this efficiency, one stands out as a cornerstone of modern manufacturing: the plastic sheet press machine. This innovative device has revolutionized the way plastic materials are molded and shaped, offering precision, versatility, and speed that traditional methods simply cannot match. Let's delve into the realm of plastic sheet press machines and explore how they are reshaping industries worldwide.

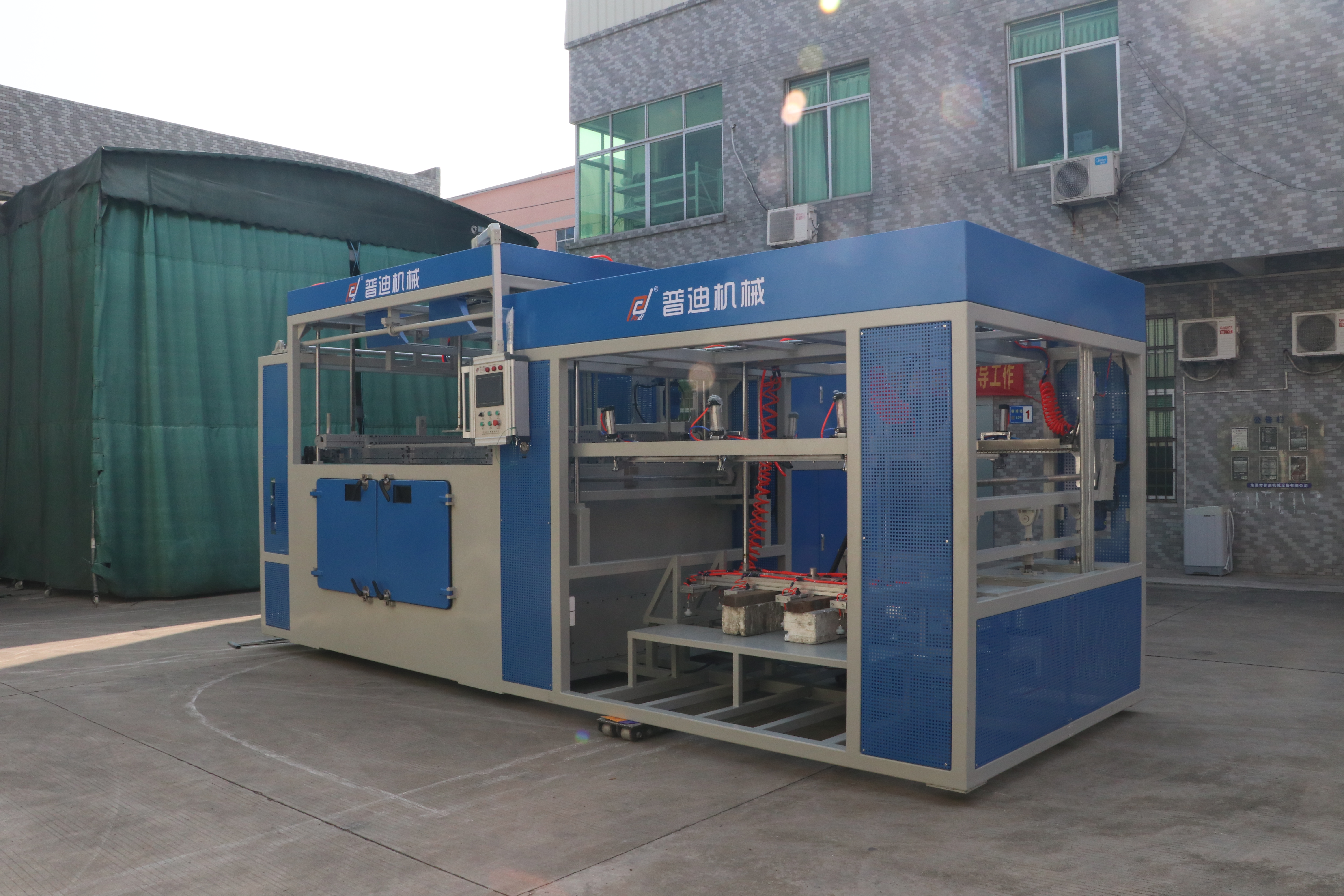

Unveiling Precision Engineering

At the heart of every plastic sheet press machine lies precision engineering. These machines are meticulously designed and built to exacting standards, ensuring consistent and accurate results with every use. Whether you're molding intricate components for automotive applications or producing precision parts for electronics, the plastic sheet press machine delivers unparalleled precision that meets the most demanding specifications. This level of accuracy not only enhances product quality but also minimizes waste, making it a valuable asset for any manufacturing operation.

Versatility in Action

One of the most compelling aspects of the plastic sheet press machine is its versatility. Unlike traditional molding methods that are limited in scope, these machines can accommodate a wide range of materials, including thermoplastics, thermosets, and composite materials. Furthermore, they can produce an array of shapes and sizes, from simple flat sheets to complex three-dimensional forms, making them ideal for a diverse range of applications. Whether you're manufacturing consumer goods, industrial components, or aerospace parts, the plastic sheet press machine offers the flexibility to adapt to your specific needs.

Efficiency at Its Core

In today's fast-paced manufacturing environment, efficiency is key to success. The plastic sheet press machine excels in this regard, thanks to its rapid cycle times and automated operation. By streamlining the molding process and minimizing manual intervention, these machines optimize productivity and reduce production costs. Additionally, their energy-efficient design helps lower operating expenses while maximizing throughput, ensuring that manufacturers can meet increasing demands without sacrificing quality or profitability.

Innovative Solutions for Modern Challenges

As industries evolve and technology advances, manufacturers are faced with new challenges and opportunities. The plastic sheet press machine represents an innovative solution to these modern challenges, offering a combination of cutting-edge technology and proven reliability. Whether you're seeking to improve product performance, reduce time-to-market, or enhance sustainability, these machines provide the tools and capabilities to achieve your goals. With their ability to deliver consistent results in a fast-paced environment, they empower manufacturers to stay ahead of the curve and capitalize on emerging trends.

Conclusion: Embracing the Future of Manufacturing

In conclusion, the plastic sheet press machine is more than just a piece of equipment; it's a catalyst for innovation and growth. With its precision engineering, versatility, efficiency, and ability to address modern manufacturing challenges, it is reshaping industries and driving progress across the globe. Whether you're a seasoned manufacturer or a forward-thinking entrepreneur, investing in a plastic sheet press machine is a strategic decision that promises to unlock new possibilities and propel your business into the future.

Ready to elevate your manufacturing capabilities? Contact us today to learn more about our range of plastic sheet press machines and discover how they can revolutionize your production processes.