Egg Tray Vacuum Forming Machine: An Essential Tool in the Packaging Industry

In the ever-evolving world of packaging, the egg tray vacuum forming machine has emerged as a key solution for industries aiming to produce high-quality and environmentally friendly egg trays. These machines are designed to efficiently produce egg trays from recycled paper materials, playing a crucial role in protecting fragile eggs during transportation and storage. This blog will explore the features, benefits, and applications of the egg tray vacuum forming machine, as well as how it can enhance productivity in the packaging sector.

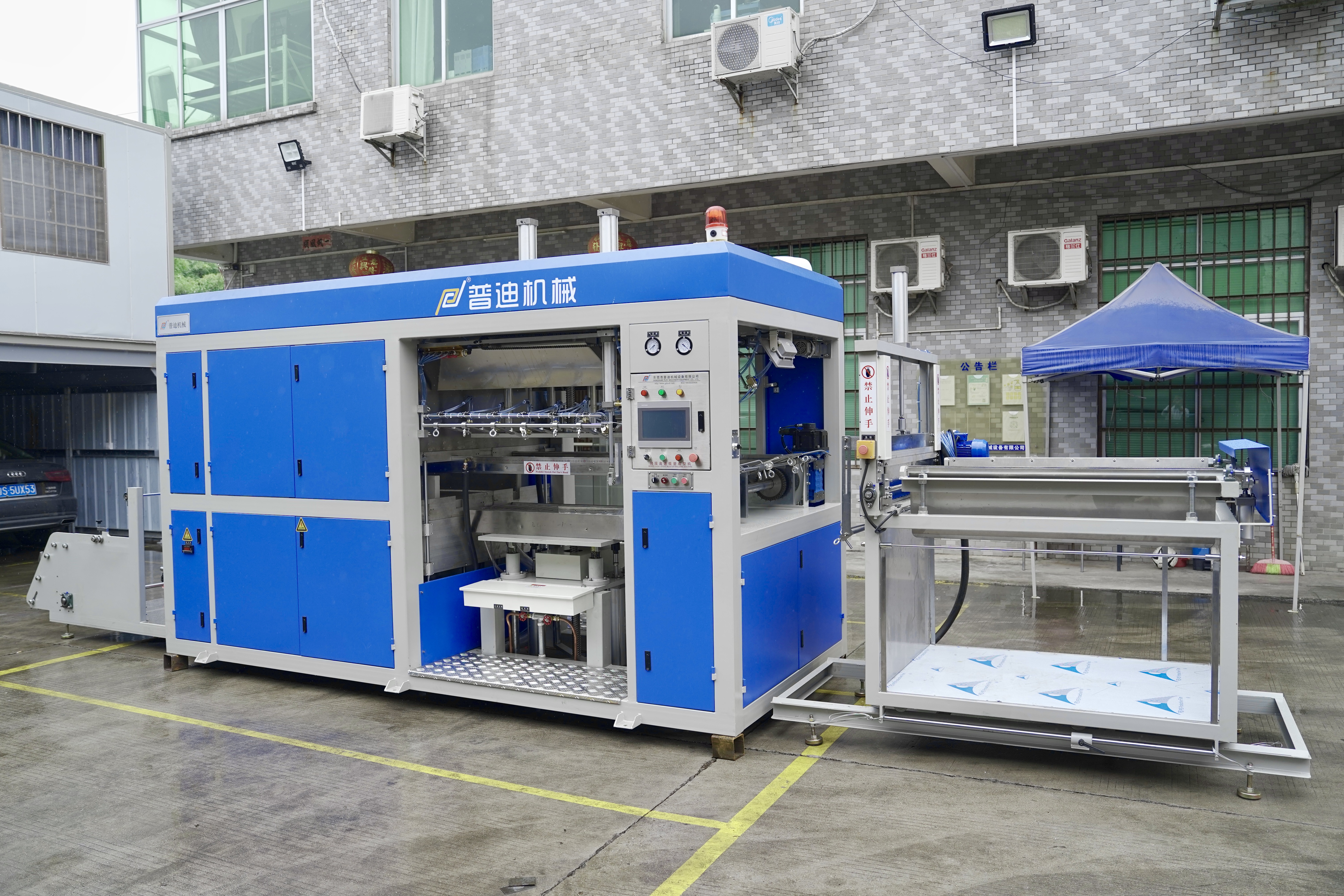

Understanding the Egg Tray Vacuum Forming Machine

The egg tray vacuum forming machine is a specialized device used to manufacture egg trays through a process that molds wet pulp into the desired shape using vacuum pressure. This machine operates using a combination of heat, pressure, and suction to form trays that are durable, lightweight, and protective.

How Does the Egg Tray Vacuum Forming Machine Work?

The process begins by preparing the raw materials, typically recycled paper or cardboard, which are pulped with water to create a slurry. The forming machine uses a mold and vacuum suction to shape the slurry into the required egg tray structure. After the trays are formed, they are dried and sometimes hardened to improve their durability.

Key components of an egg tray vacuum forming machine include:

- Pulping system: Prepares the raw material by mixing water and recycled paper.

- Molding system: The vacuum pressure molds the pulp into trays.

- Drying system: Ensures the trays are fully dried to prevent deformation.

Each of these components plays an important role in ensuring the quality and efficiency of the production process.

Benefits of Using an Egg Tray Vacuum Forming Machine

1. Eco-Friendly Production

One of the major benefits is its environmental impact. These machines utilize recycled materials to produce trays, reducing the need for new raw resources and minimizing waste. With increasing pressure on companies to adopt sustainable practices, this machine is a vital tool in creating eco-friendly packaging solutions.

2. Cost-Effectiveness

The forming machine helps companies save on material costs since it uses recycled paper. Additionally, the automated nature of the machine reduces labor costs by streamlining the manufacturing process. This makes it an attractive investment for businesses in the packaging industry that are looking to maximize their efficiency and profitability.

3. High Output and Efficiency

These machines are capable of producing thousands of egg trays per hour, depending on their size and configuration. The efficiency ensures that businesses can meet the high demand for egg trays in the market while maintaining consistent quality.

4. Customizable Tray Designs

The flexibility allows for the creation of customized tray designs to meet the specific needs of different clients. Whether producing trays for standard egg sizes or custom packaging for other fragile products, these machines can be tailored to produce a variety of shapes and sizes.

5. Durable and Lightweight Packaging

Egg trays produced by these machines are lightweight, making them easy to handle and transport. At the same time, they provide excellent protection for eggs, reducing the risk of damage during shipping.

Key Applications of the Egg Tray Vacuum Forming Machine

While the primary application is to produce egg trays, its versatility extends beyond this single function. The machine can be used to create various types of molded pulp packaging products, including:

- Fruit trays: Designed for holding delicate fruits like apples and peaches.

- Wine bottle holders: To protect bottles during transportation.

- Electronic product packaging: For protecting fragile electronics.

- Medical product trays: For organizing and protecting medical equipment during transport.

Choosing the Right Egg Tray Vacuum Forming Machine Factory

When it comes to investing in an egg tray vacuum forming machine, it’s essential to choose a reliable factory that manufactures high-quality machines. Look for a factory with a proven track record, strong customer support, and machines that are built to last. A good egg tray vacuum forming machine factory will provide not only top-of-the-line equipment but also training, maintenance, and after-sales support.

Factors to consider when choosing a factory include:

- Machine quality: The materials used in the construction of the machine should be durable and capable of withstanding heavy use.

- Customization options: The factory should offer machines that can be tailored to meet the specific needs of your business.

- Energy efficiency: Modern machines are designed to be energy-efficient, reducing operational costs over time.

- Technical support: A good factory will offer ongoing technical support to ensure the machine continues to perform optimally.

Maintenance and Care for Egg Tray Vacuum Forming Machines

Proper maintenance of your machine is essential to ensuring its longevity and consistent performance. Regular maintenance tasks include:

- Cleaning: Keep the machine clean to prevent blockages in the vacuum system and ensure smooth operation.

- Lubrication: Regularly lubricate moving parts to reduce wear and tear.

- Inspection: Conduct routine inspections of the molding and drying systems to identify and resolve any potential issues early.

- Part replacement: Replace worn-out components as needed to prevent breakdowns.

Advancements in Egg Tray Vacuum Forming Technology

As technology continues to evolve, the machine has seen significant advancements, leading to even greater efficiency and performance. Some of the latest innovations include:

- Automated controls: Many machines now come equipped with advanced control systems that allow for precise monitoring and adjustments during production.

- Energy-saving designs: Newer machines are designed to consume less energy while maintaining high output, reducing overall operating costs.

- Improved molds: High-quality molds now allow for more detailed and accurate tray designs, improving the protection offered by the trays.

Conclusion: The Future of Egg Tray Production

In conclusion, the egg tray vacuum forming machine is an indispensable asset for businesses in the packaging industry. Its ability to produce high-quality, eco-friendly trays at a rapid pace makes it a valuable tool for companies looking to improve both their environmental impact and production efficiency. As more companies adopt sustainable practices, demand for these machines is expected to rise, making them an important investment for the future.

For businesses seeking to increase their output and reduce waste, investing in an egg tray vacuum forming machine from a reputable factory is a wise decision. With its proven ability to deliver quality, efficiency, and sustainability, this machine will continue to play a key role in the future of packaging solutions.