Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

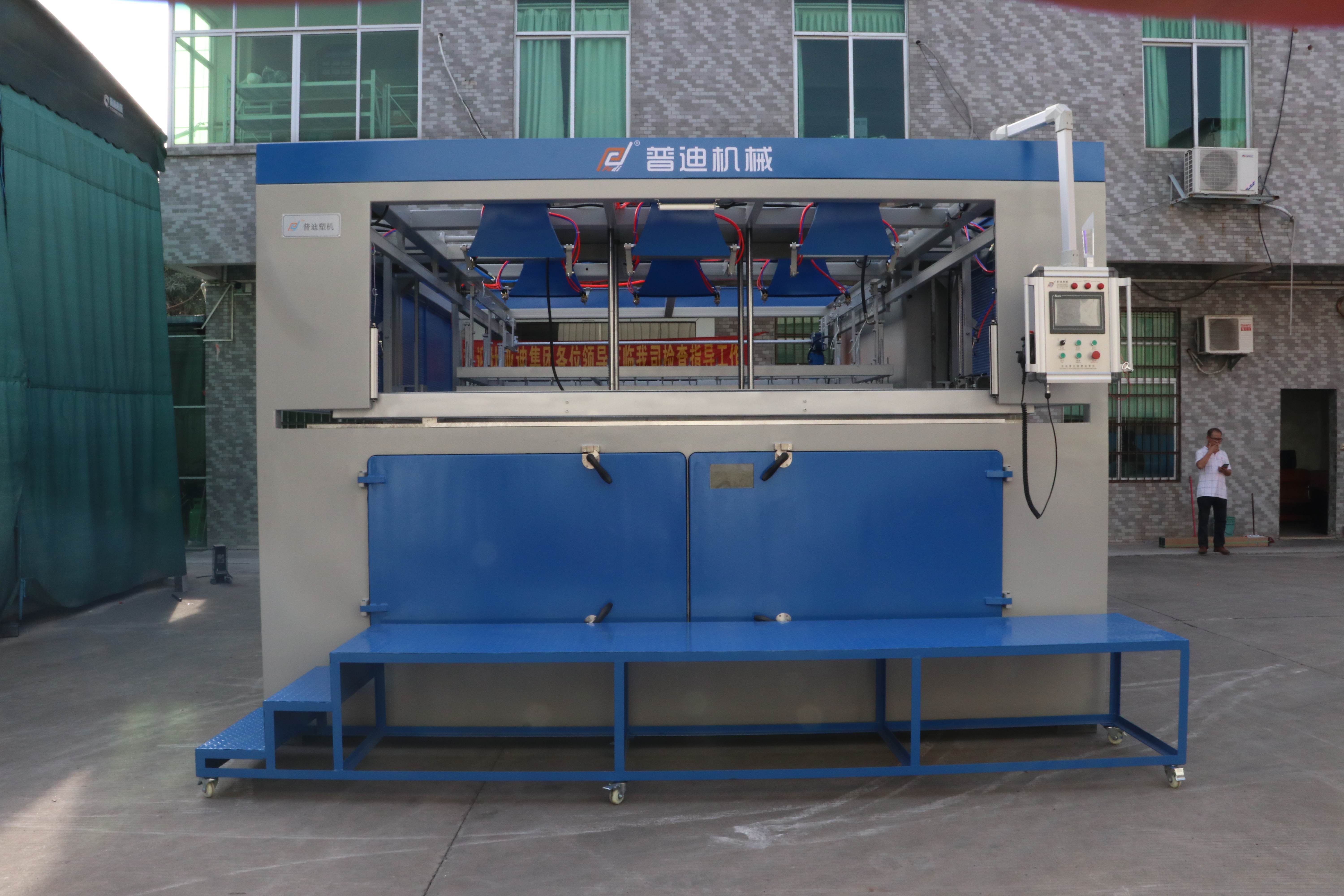

The plastic tray vacuum forming machine is made of high quality steel, it can resist of the rust year by year. It is equipped with the cooling system, and in cooling, it has no shocks or leak rest of the winds from the fan, so it can efficiently improve the production efficiency. It can automatically help you to increase the production output with accurate analysis and limited materials.

Improve the Production Efficiency:

The machine can produce plastic trays at a faster rate than manual methods, which can increase the production output. It can also automate the entire process of forming plastic trays, which reduces the need for manual labor and increases the efficiency of the production line. Besides, the machine will optimize the use of plastic material to reduce waste and save costs.

High Quality Steel:

The main body is mainly made of high quality steel, so it is very sturdy and strong, and you do not worry that it will be easily damaged, it can resist of strong power. The reason why the machine is a little heavy is because that the useful intelligent and sturdy components composite the machine to make it multifunctional. Therefore, it can withstand strong winds and store in terrible environment.

Product Parameter:

|

Maximum Wellhead Size |

2600mm*1600mm |

|

Forming Depth |

500 mm |

|

Applicable Material Thickness |

1-10mm |

|

Main Switch |

three-phase five-wire 380V±15V, 50Hz |

|

Heating Power |

Upper Furnace: 128kw; Lower Furnace: 128kw; |

|

Total Power |

280kw (subject to actual conditions, normal use is between 50-70%) |

|

Mold Forming Method |

Concave-convex molding (one-shot molding) |

|

Electric Furnace Power |

Frequency Conversion Motor Drive |

|

Die Power |

Servo Motor (both upper and lower mold tables are driven by servo) |

|

Cooling Form |

Powerful Fan |

|

Heating Unit |

fast medium-wave infrared heating tube, analog voltage regulation and temperature control |

|

Vacuum State |

Matching Large or Small Secondary Vacuum |

|

Upper Frame Structure |

It can be adjusted arbitrarily according to the different mold sizes |

|

Sheet Conveying |

Manual Placement |

|

Product Demoulding and Pick-up |

Air Pressure Blowback Demoulding |

|

Other Functions |

Bubble Blowing, Anti-sag, Large and Small Vacuum |

|

Adaptable Processing Materials |

PP. PC. PE. PVC. ABS. PS and other thermoplastic sheets |

|

Machine Dimension |

3800mm*4600mm*3200mm (excluding the upper mold) |