Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

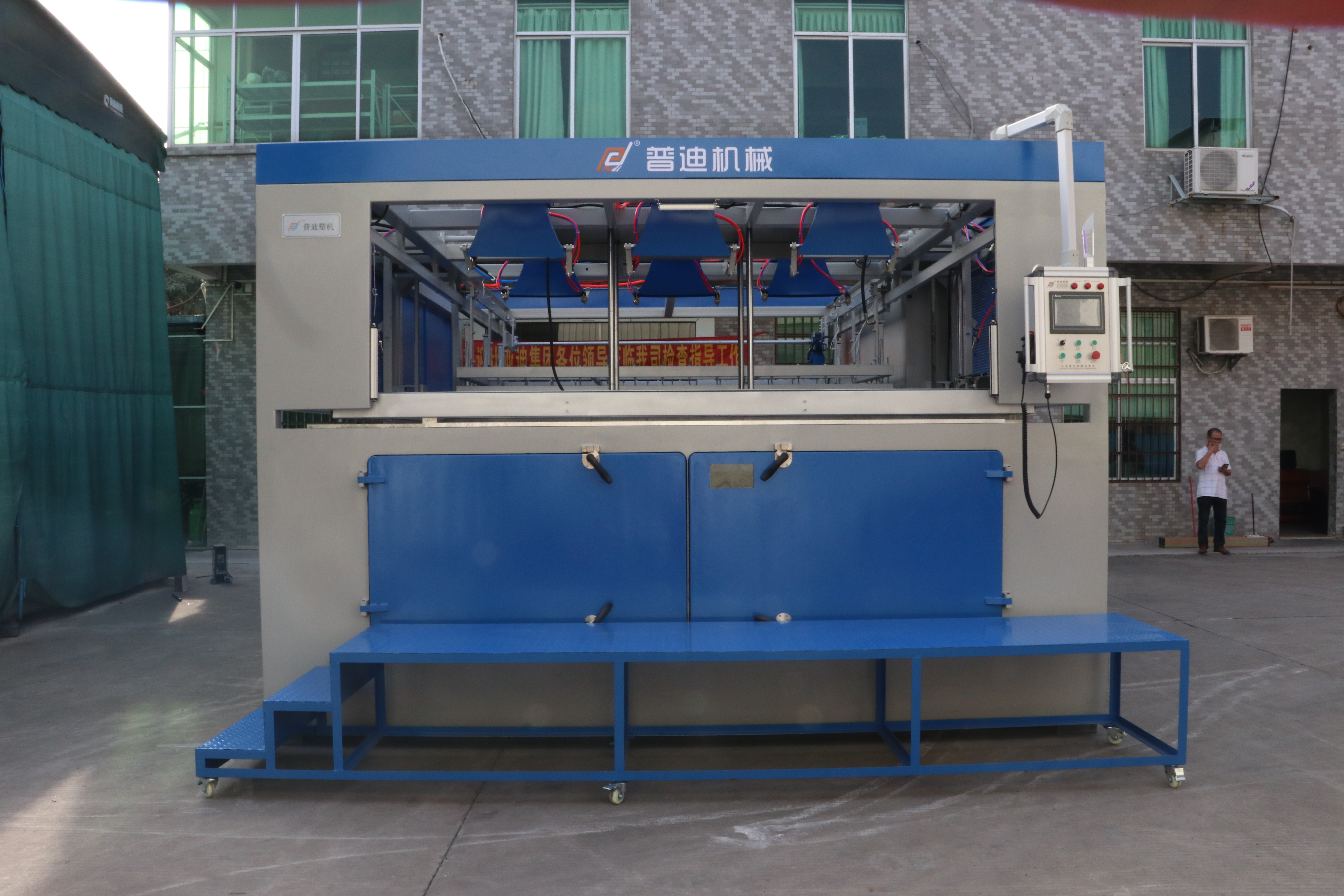

The equipment shell vacuum forming machine is environmental friendly, because it can reduce the production cost according to its intelligent analysis and treatment. It ensures that the each shell produced is in the same size and quality, which allows you to receive larger deal, so that you can earn more money with the reduction of the production cost. The cooling system and heating system can work simultaneously to make the shells in good quality and not easy to be broken.

High Efficiency:

The equipment shell vacuum forming machine is designed to provide high efficiency in the production of equipment shells. Its advanced technology and low power consumption make it an ideal choice for businesses looking to reduce costs while optimizing their production. It is equipped with a powerful vacuum system that quickly and effectively forms the desired shape of the equipment shell. It also has a wide range of adjustable parameters, allowing you to customize the product to your exact needs. If you want to customize different kind of products, you can choose to change the mould, then to be used as much as possible.

Customized Service:

Our commitment is to make all customers with biggest satisfaction, and we are responsible for all machine that we sold, so if you meet any problem after you received, you can contact with us at once, and we will try our best to solve your problem. If you have any idea for the size, color, material, and shape, you can also tell us. If you want to get quick quote, we suggest that you can give us your drawings as quick as possible, then our professionals will have thoughts about the manufacture.

Product Parameter:

|

Maximum Wellhead Size |

2600mm*1600mm |

|

Forming Depth |

500 mm |

|

Applicable Material Thickness |

1-10mm |

|

Main Switch |

three-phase five-wire 380V±15V, 50Hz |

|

Heating Power |

Upper Furnace: 128kw; Lower Furnace: 128kw; |

|

Total Power |

280kw (subject to actual conditions, normal use is between 50-70%) |

|

Mold Forming Method |

Concave-convex molding (one-shot molding) |

|

Electric Furnace Power |

Frequency Conversion Motor Drive |

|

Die Power |

Servo Motor (both upper and lower mold tables are driven by servo) |

|

Cooling Form |

Powerful Fan |

|

Heating Unit |

fast medium-wave infrared heating tube, analog voltage regulation and temperature control |

|

Vacuum State |

Matching Large or Small Secondary Vacuum |

|

Upper Frame Structure |

It can be adjusted arbitrarily according to the different mold sizes |

|

Sheet Conveying |

Manual Placement |

|

Product Demoulding and Pick-up |

Air Pressure Blowback Demoulding |

|

Other Functions |

Bubble Blowing, Anti-sag, Large and Small Vacuum |

|

Adaptable Processing Materials |

PP. PC. PE. PVC. ABS. PS and other thermoplastic sheets |

|

Machine Dimension |

3800mm*4600mm*3200mm (excluding the upper mold) |