Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

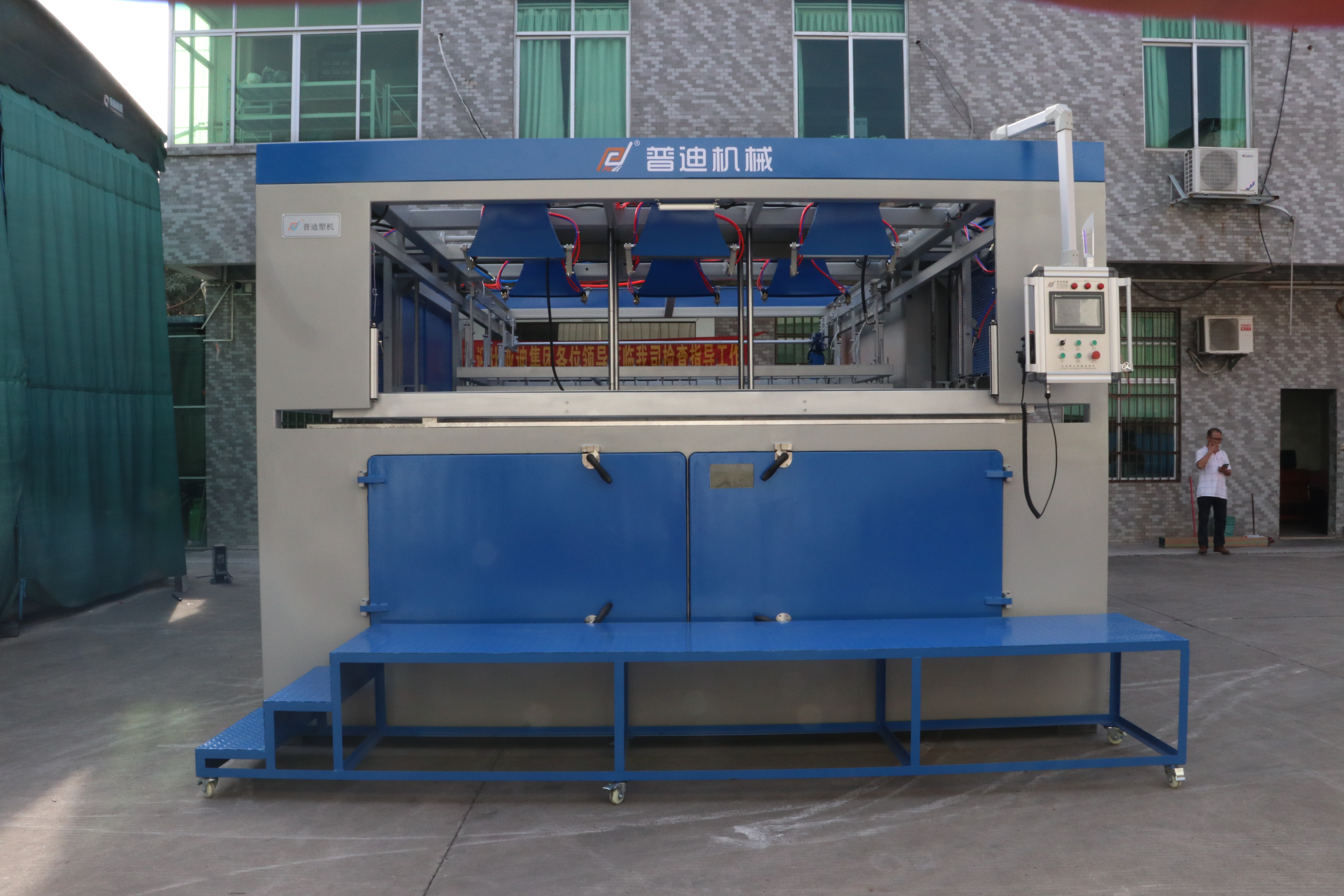

The automotive instrument panel vacuum forming machine is well equipped with good ventilation to guarantee that the heat can be well released. The inner electric line is well stored by components, so you do not worry that it will be easily damaged with naked in the air. The heating board made is also high-temperature resistant, it’s no risk for it to be burnt. It can produce high quality automotive instrument panel to make it maintain and use in many years.